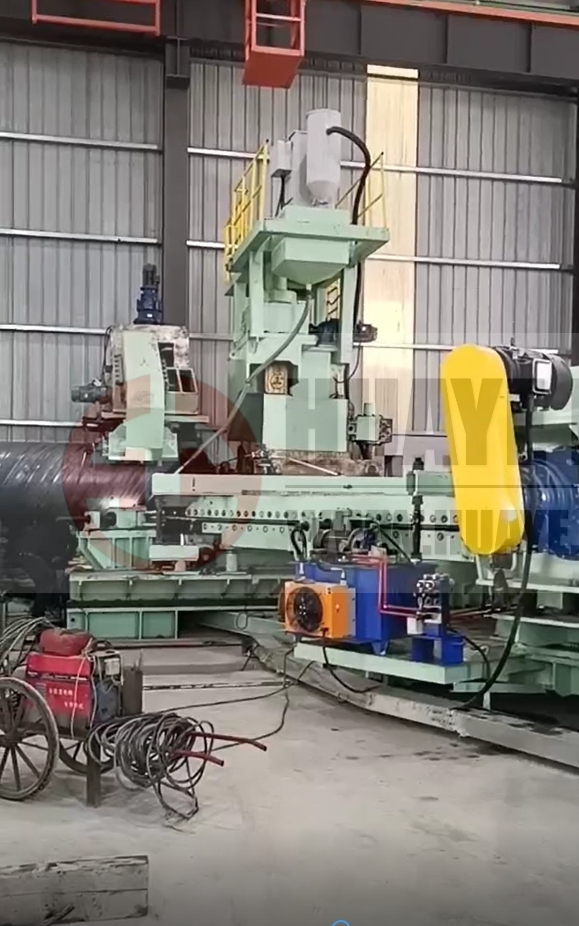

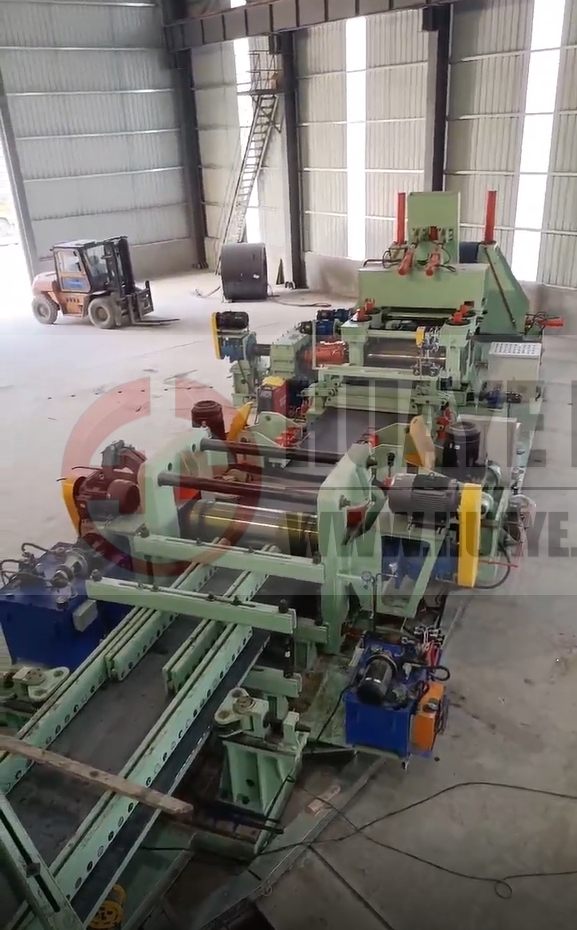

1420 Spiral Pipe Mill Successfully Produced with First Welded Pipe Off the Line!

25 Dec,2024

Good news! The 1420mm spiral welded pipe mill has successfully started after careful commissioning and testing, and the first welded pipe has been successfully produced.

Equipment parameters:

- Plate width: 700 - 1550 mm

- Pipe diameter: Φ400 –Φ1420 mm

- Wall thickness: 6-16 mm

- Pipe length: 8 - 12 m

The completion of this project embodies the wisdom and hard work of the Huaye research team and production workers. From the careful selection of raw materials to the strict control of production processes, every step reflects an unwavering pursuit of quality. This is not only a practical test of the mill's performance but also lays a solid foundation for subsequent mass production of high-quality welded pipes. With the full production of this mill, it is expected to effectively enhance the regional steel pipe supply capacity, promote the coordinated development of upstream and downstream industrial chains, and provide stronger material support for local infrastructure construction, contributing to high-quality economic and social development.

If you are interested in similar equipment, please feel free to contact us info@huaye.us!

Key words:

- All

- Product Management

- News

- Introduction

- Enterprise outlets

- FAQ

- Enterprise Video

- Enterprise Atlas

Related News

How to Ensure Your Pipe Welding Equipment Meets Industry Standards

2025-12-03

Essential Guide to Pipe Welding Equipment for Efficient Manufacturing

2025-11-28

Pipe Welding Equipment: A Comprehensive Exploration of Features and Advantages

2025-11-23