Pipe Welding Equipment: A Comprehensive Exploration of Features and Advantages

23 Nov,2025

Pipe Welding Equipment: A Comprehensive Exploration of Features and Advantages

Table of Contents

1. Introduction to Pipe Welding Equipment

2. Types of Pipe Welding Equipment

3. Key Features of Pipe Welding Tools

4. Benefits of Using Electric Pipe Welding Equipment

5. The Role of Beveling Machines in Pipe Welding

6. Choosing the Right Pipe Welding Equipment

7. Maintenance Tips for Pi

Pipe Welding Equipment: A Comprehensive Exploration of Features and Advantages

Table of Contents

- 1. Introduction to Pipe Welding Equipment

- 2. Types of Pipe Welding Equipment

- 3. Key Features of Pipe Welding Tools

- 4. Benefits of Using Electric Pipe Welding Equipment

- 5. The Role of Beveling Machines in Pipe Welding

- 6. Choosing the Right Pipe Welding Equipment

- 7. Maintenance Tips for Pipe Welding Tools

- 8. Frequently Asked Questions

- 9. Conclusion

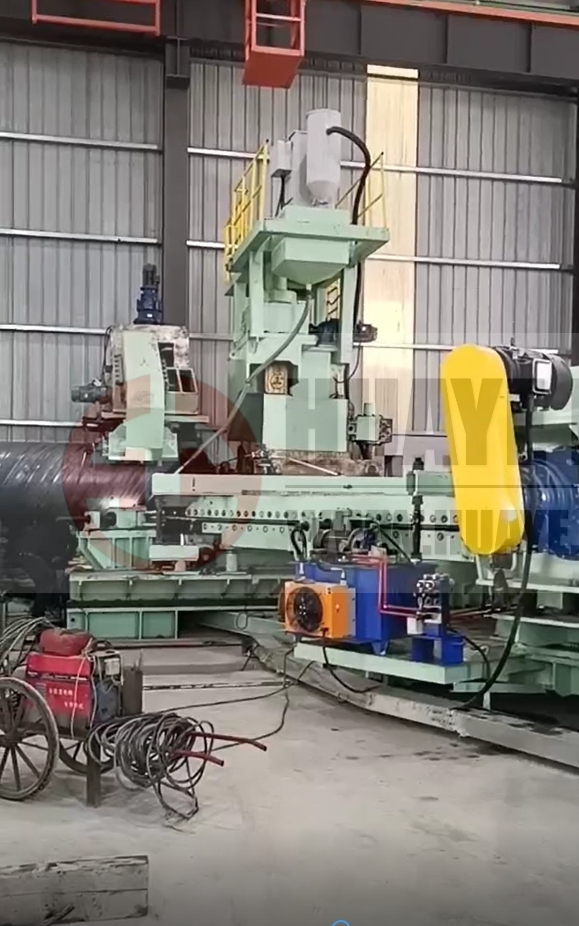

1. Introduction to Pipe Welding Equipment

Pipe welding is a crucial process in various industries, including oil and gas, construction, and manufacturing. The equipment used in this process must be robust, reliable, and efficient. In this article, we will dive deep into the features and benefits of pipe welding equipment, helping you understand how it can enhance your projects.

2. Types of Pipe Welding Equipment

When considering pipe welding, it’s essential to recognize the various types of equipment available. These include:

2.1 Electric Welding Machines

Electric welding machines are widely used for their ease of use and flexibility. They come in different models, including MIG (Metal Inert Gas) and TIG (Tungsten Inert Gas) welding machines.

2.2 Beveling Machines

Beveling machines are specialized tools designed to prepare pipe edges for welding. They ensure that the pipes fit together perfectly, which is vital for creating strong welds.

2.3 Plasma Cutters

Plasma cutters are ideal for cutting through thick materials and are often used in conjunction with welding equipment to create precise cuts.

3. Key Features of Pipe Welding Tools

Understanding the features of pipe welding tools can help you make informed decisions. Some key features include:

3.1 Portability

Many electric pipe welding machines are designed to be portable, allowing for easy transportation to job sites. This feature is particularly beneficial for contractors who work on various projects.

3.2 Digital Controls

Modern pipe welding equipment often includes digital controls that facilitate accurate settings for voltage, amperage, and wire feed speed. These controls enhance the precision of the welding process.

3.3 Versatility

Pipe welding tools can be used for various materials, such as stainless steel, aluminum, and carbon steel. This versatility expands the range of applications for these machines.

3.4 Safety Features

Safety is paramount in welding. Many modern machines come equipped with safety features, including automatic shutoff, thermal overload protection, and spark guards.

4. Benefits of Using Electric Pipe Welding Equipment

Investing in electric pipe welding equipment offers numerous advantages:

4.1 Efficiency and Speed

Electric welding machines generally operate faster than their gas counterparts, allowing for quicker project completion. This efficiency translates to reduced labor costs and increased productivity.

4.2 Consistency in Weld Quality

Electric welding provides a more consistent heat source, resulting in uniform welds. This consistency is crucial in maintaining the structural integrity of welded joints.

4.3 Lower Operating Costs

Electric welding equipment typically has lower operating costs compared to gas machines. This cost-effectiveness makes it a preferred choice for many businesses.

4.4 Environmentally Friendly

Electric welding machines produce fewer emissions and noise, making them a more environmentally friendly option.

5. The Role of Beveling Machines in Pipe Welding

Beveling machines play a critical role in pipe welding by ensuring that the edges of the pipes are properly shaped for welding. This process minimizes the risk of defects and enhances the quality of the weld.

5.1 Types of Bevels

There are several types of bevels, including square, single, and double bevels. The type of bevel used often depends on the welding process and the materials being welded.

5.2 Benefits of Proper Beveling

Proper beveling leads to improved fit-up between pipes, greater weld penetration, and reduced risk of weld failure. It ultimately contributes to the overall success of the welding project.

6. Choosing the Right Pipe Welding Equipment

Selecting the appropriate pipe welding equipment depends on various factors, including the material type, project scale, and budget. Here are some tips for making the right choice:

6.1 Assess Your Project Requirements

Consider the specific requirements of your project, such as the type of material and thickness of the pipes. This assessment will guide you in selecting the appropriate equipment.

6.2 Research Brands and Models

Take the time to research different brands and models of welding equipment. Look for reviews and testimonials from other users to gauge the reliability and performance of the equipment.

6.3 Consider After-Sales Support

Opt for manufacturers that provide excellent after-sales support, including training, maintenance, and repair services. This support can be invaluable in ensuring the longevity of your equipment.

7. Maintenance Tips for Pipe Welding Tools

Proper maintenance is essential for ensuring the longevity and performance of pipe welding tools. Here are some maintenance tips:

7.1 Regular Cleaning

Keep your welding equipment clean to prevent buildup that can affect performance. Wipe down surfaces after use, and ensure that all components are free from dust and debris.

7.2 Inspect Cables and Connections

Regularly inspect cables and connections for any signs of wear or damage. Replace any faulty components immediately to prevent accidents.

7.3 Calibration

Periodically calibrate your equipment to ensure it operates at optimal settings. This practice helps maintain consistent weld quality.

8. Frequently Asked Questions

8.1 What are the different welding techniques used in pipe welding?

The common welding techniques used in pipe welding include MIG, TIG, Stick, and Flux-Cored Arc Welding (FCAW).

8.2 How do I determine the right size welding machine for my project?

The right size welding machine depends on the thickness and type of material you are welding, as well as the type of welding technique you plan to use.

8.3 Are there specific safety gear requirements for welding?

Yes, welders should wear appropriate safety gear, including helmets, gloves, protective clothing, and eye protection.

8.4 How often should welding equipment be serviced?

Welding equipment should be serviced regularly, typically at least once a year or after significant use, to ensure optimal performance.

8.5 Can I use electric welding equipment outdoors?

Yes, but it is essential to ensure that the equipment is rated for outdoor use and that appropriate safety precautions are taken to protect against weather conditions.

9. Conclusion

In summary, understanding pipe welding equipment's features and benefits is vital for anyone involved in manufacturing and construction. The right tools can significantly impact the efficiency and quality of welding projects. By choosing high-quality electric welding machines and beveling tools, and ensuring proper maintenance, you can enhance your welding capabilities and achieve outstanding results. Whether you are a seasoned professional or a newcomer to the field, staying informed about the latest equipment and techniques will ultimately lead you to success in your projects.

Key words:

All

- All

- Product Management

- News

- Introduction

- Enterprise outlets

- FAQ

- Enterprise Video

- Enterprise Atlas

Related News

Understanding Tube Beveling Machines: Essential Knowledge for Manufacturing Professionals

---

In the realm of manufacturing and processing machinery, tube beveling machines play a significant role in preparing tubes and pipes for welding and other applications. These machines are designed to create a beveled edge on the ends of tubes, which facilitates better joint fit-up and improves the overall quality of welds. Understanding the features and benefits of tube beveling machines is ess

2025-12-30

Choosing the Right Pipe Prepping Machine: Essential Factors to Consider

Choosing the Right Pipe Prepping Machine: Essential Factors to Consider

When it comes to manufacturing and construction, the right tools can make all the difference in achieving efficiency and reliability. One pivotal piece of equipment in this realm is the pipe prepping machine. Selecting the appropriate pipe prepping machine is crucial, as it directly impacts the quality of your work, the ease o

2025-12-23

Essential Insights into Pipe Prepping Machines for Precision Manufacturing

In the realm of manufacturing and processing machinery, the role of a pipe prepping machine cannot be overstated. These specialized machines are designed to prepare pipes for various applications, ensuring that the edges are uniformly shaped and ready for welding or assembly. The significance of a pipe prepping machine is particularly pronounced in industries where precision and efficiency are par

2025-12-18