Essential Insights into Pipe Welding Equipment: A Guide for Professionals

18 Nov,2025

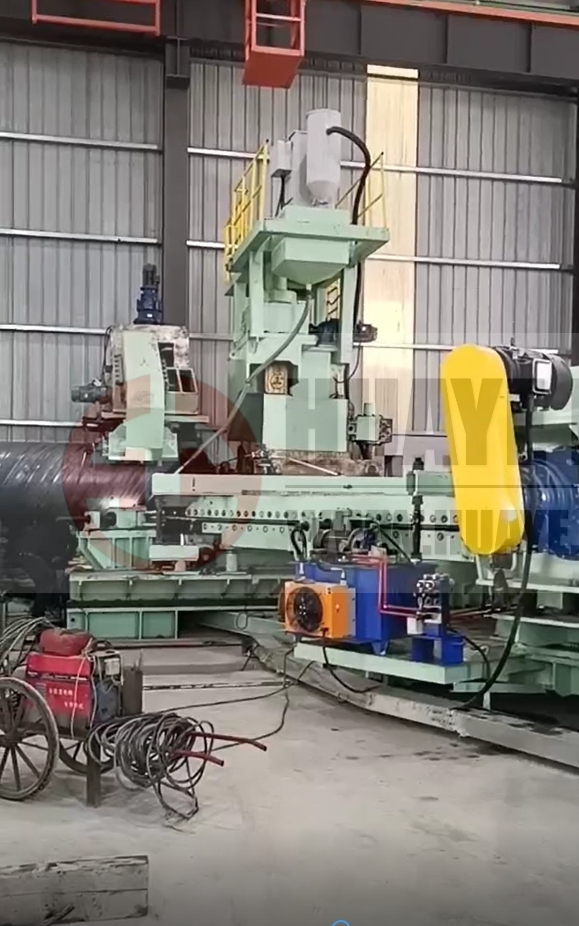

When it comes to pipe welding equipment, understanding its components and functionalities is crucial for professionals in the manufacturing and mechanical processing industry. Pipe welding is a critical process used to join metal pipes for various applications, including plumbing, construction, and industrial machinery. The efficiency and quality of these welds largely depend on the equipment used

When it comes to pipe welding equipment, understanding its components and functionalities is crucial for professionals in the manufacturing and mechanical processing industry. Pipe welding is a critical process used to join metal pipes for various applications, including plumbing, construction, and industrial machinery. The efficiency and quality of these welds largely depend on the equipment used, making it essential for professionals to stay informed.

At the core of pipe welding equipment are welding machines, which can vary significantly in type and application. Common types include TIG (Tungsten Inert Gas) welders, MIG (Metal Inert Gas) welders, and stick welders. Each has its unique advantages: TIG welding provides high precision and is ideal for thin materials, while MIG welding is known for its speed and efficiency, making it suitable for thicker materials. Stick welding is versatile and widely used for outdoor applications due to its resistance to wind and contamination.

In addition to the welding machines, several accessories play a critical role in achieving high-quality welds. These include welding torches, electrodes, and filler materials. Selecting the appropriate filler material is vital, as it affects the strength and integrity of the weld. Moreover, protective gear, such as helmets and gloves, is essential to ensure the safety of the operator during the welding process.

Another critical aspect of pipe welding equipment is the ability to perform accurate beveling on the pipe edges before welding. This is where electric beveling machines come into play. They are designed to create precise angles on the pipe edges, ensuring a better fit and stronger weld. The quality of the bevel can significantly influence the overall strength of the welded joint, making electric beveling machines an indispensable tool in the welding process.

It is also important to consider the maintenance of pipe welding equipment. Regular checks and maintenance can prevent malfunctions and ensure longevity, which is crucial for operating efficiency. Professionals should routinely assess the condition of their equipment and replace any worn or damaged components promptly.

In conclusion, understanding pipe welding equipment is fundamental for any professional engaged in manufacturing and mechanical processing. From selecting the appropriate welding machine to ensuring proper beveling and maintenance, every decision impacts the quality and durability of the weld. By staying informed about the advancements and best practices in pipe welding technologies, professionals can enhance their skills and contribute to more efficient and safer welding operations.

At the core of pipe welding equipment are welding machines, which can vary significantly in type and application. Common types include TIG (Tungsten Inert Gas) welders, MIG (Metal Inert Gas) welders, and stick welders. Each has its unique advantages: TIG welding provides high precision and is ideal for thin materials, while MIG welding is known for its speed and efficiency, making it suitable for thicker materials. Stick welding is versatile and widely used for outdoor applications due to its resistance to wind and contamination.

In addition to the welding machines, several accessories play a critical role in achieving high-quality welds. These include welding torches, electrodes, and filler materials. Selecting the appropriate filler material is vital, as it affects the strength and integrity of the weld. Moreover, protective gear, such as helmets and gloves, is essential to ensure the safety of the operator during the welding process.

Another critical aspect of pipe welding equipment is the ability to perform accurate beveling on the pipe edges before welding. This is where electric beveling machines come into play. They are designed to create precise angles on the pipe edges, ensuring a better fit and stronger weld. The quality of the bevel can significantly influence the overall strength of the welded joint, making electric beveling machines an indispensable tool in the welding process.

It is also important to consider the maintenance of pipe welding equipment. Regular checks and maintenance can prevent malfunctions and ensure longevity, which is crucial for operating efficiency. Professionals should routinely assess the condition of their equipment and replace any worn or damaged components promptly.

In conclusion, understanding pipe welding equipment is fundamental for any professional engaged in manufacturing and mechanical processing. From selecting the appropriate welding machine to ensuring proper beveling and maintenance, every decision impacts the quality and durability of the weld. By staying informed about the advancements and best practices in pipe welding technologies, professionals can enhance their skills and contribute to more efficient and safer welding operations.

Key words:

All

- All

- Product Management

- News

- Introduction

- Enterprise outlets

- FAQ

- Enterprise Video

- Enterprise Atlas

Related News

Understanding Tube Beveling Machines: Essential Knowledge for Manufacturing Professionals

---

In the realm of manufacturing and processing machinery, tube beveling machines play a significant role in preparing tubes and pipes for welding and other applications. These machines are designed to create a beveled edge on the ends of tubes, which facilitates better joint fit-up and improves the overall quality of welds. Understanding the features and benefits of tube beveling machines is ess

2025-12-30

Choosing the Right Pipe Prepping Machine: Essential Factors to Consider

Choosing the Right Pipe Prepping Machine: Essential Factors to Consider

When it comes to manufacturing and construction, the right tools can make all the difference in achieving efficiency and reliability. One pivotal piece of equipment in this realm is the pipe prepping machine. Selecting the appropriate pipe prepping machine is crucial, as it directly impacts the quality of your work, the ease o

2025-12-23

Essential Insights into Pipe Prepping Machines for Precision Manufacturing

In the realm of manufacturing and processing machinery, the role of a pipe prepping machine cannot be overstated. These specialized machines are designed to prepare pipes for various applications, ensuring that the edges are uniformly shaped and ready for welding or assembly. The significance of a pipe prepping machine is particularly pronounced in industries where precision and efficiency are par

2025-12-18