Contact Us

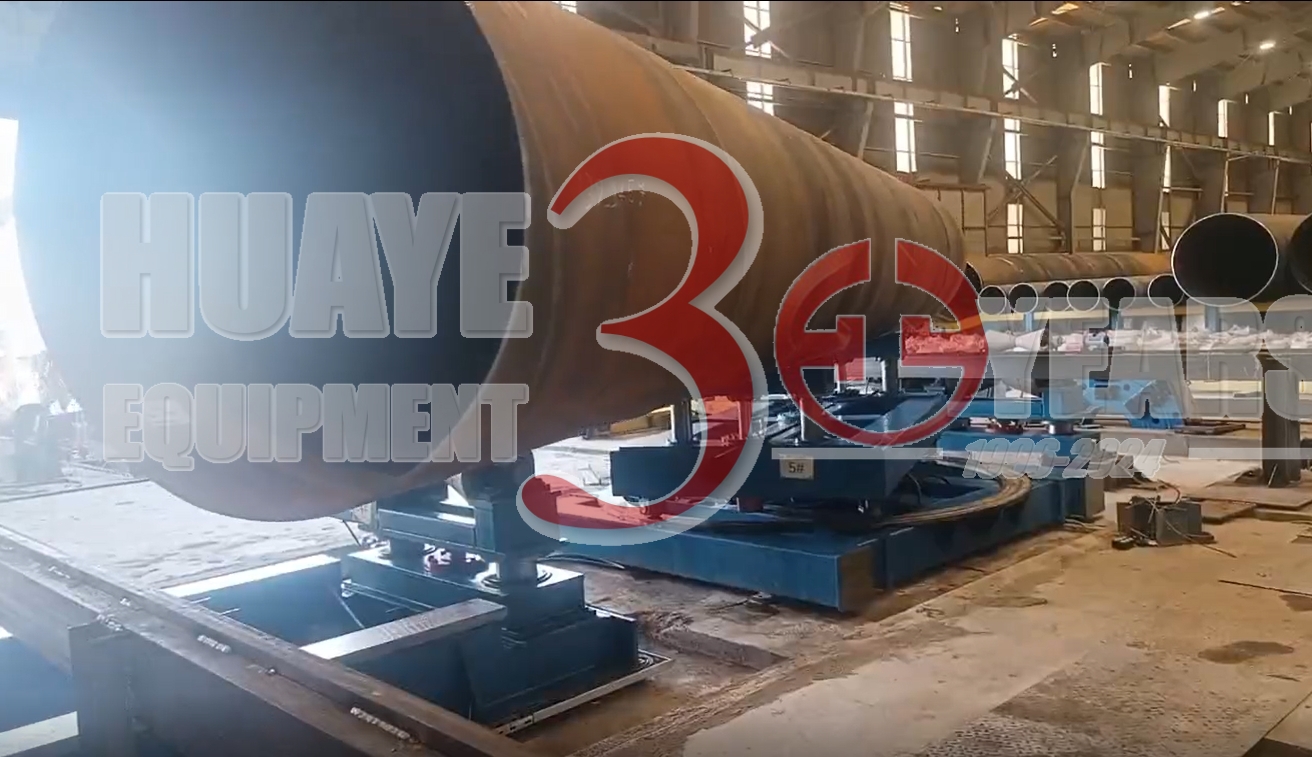

Single Head 2032mm Pipe End Facing and Beveling Machine in Iran

29 Oct,2024

This 2032mm pipe end facing and beveling machine with single head is being installed in Iran. With the smooth progress of commissioning, the successful commissioning of the project is just around the corner.

This machine is one of the steel pipe end facing and beveling machine series of our institute. This machine is arranged as a single head. The single head end facing and beveling machine is mainly used for flat head and groove processing of welded pipe ends. Compared with double-head equipment, it has only one head, which can process pipes of various lengths. After processing one end, the pipe needs to be rotated by 180 ° to process the other end. The investment is low, and it is suitable for small and medium-sized enterprises or production needs of medium and low production capacity.

Equipment Sprcifications:

- Diameter range: Φ406 ~ Φ2032mm

Wall thickness: 6-25mm

Steel pipe material: Q355

Steel pipe length: 8-12m

Cutter speed range: 80~120 m/min

Technological Process:

Steel pipe feeding → Pipe transport vehicle taking over → Pipe transport vehicle walking flat head and station → Lifting roller lifting the steel pipe to the center position of the flat head machine → Moving the base forward → Clamping → Turning the cutter head → Fast forward → Working in (flat head chamfering) → Fast backward → Unclamping → Moving the base backward → Pipe transport vehicle rotating 180 degrees → Processing the other end

In a challenging and uncertain international environment, the Huaye team showed extraordinary courage and professionalism. They braved difficulties and went deep into the Iranian site to install and debug the 2032mm single-head pipe end facing and beveling machine. In the face of complex working conditions and urgent timelines, team members work closely to overcome many difficulties and ensure that every step of the work is accurate.

After being put into operation, the equipment will be applied to the flat head and chamfering treatment of spiral welded pipes, effectively meeting the demand for high quality industrial materials in Iran and its surrounding markets, and further promoting the optimization and upgrading of the regional industrial chain. We sincerely hope that through joint efforts, we can bring more peace and development to this land, let the light of technology illuminate the way forward, and pray for the light of peace to shine on every corner as soon as possible.

If you are interested in similar products, welcome to contact us yang.wang@huaye.us.

Key words:

Pipe welding equipment

Related News

Essential Insights into Pipe Prepping Machines: A Comprehensive Guide

2025-12-08

How to Ensure Your Pipe Welding Equipment Meets Industry Standards

2025-12-03

Essential Guide to Pipe Welding Equipment for Efficient Manufacturing

2025-11-28