630 and 2540mm full set of spiral welded pipe production line being installed in China

16 Nov,2024

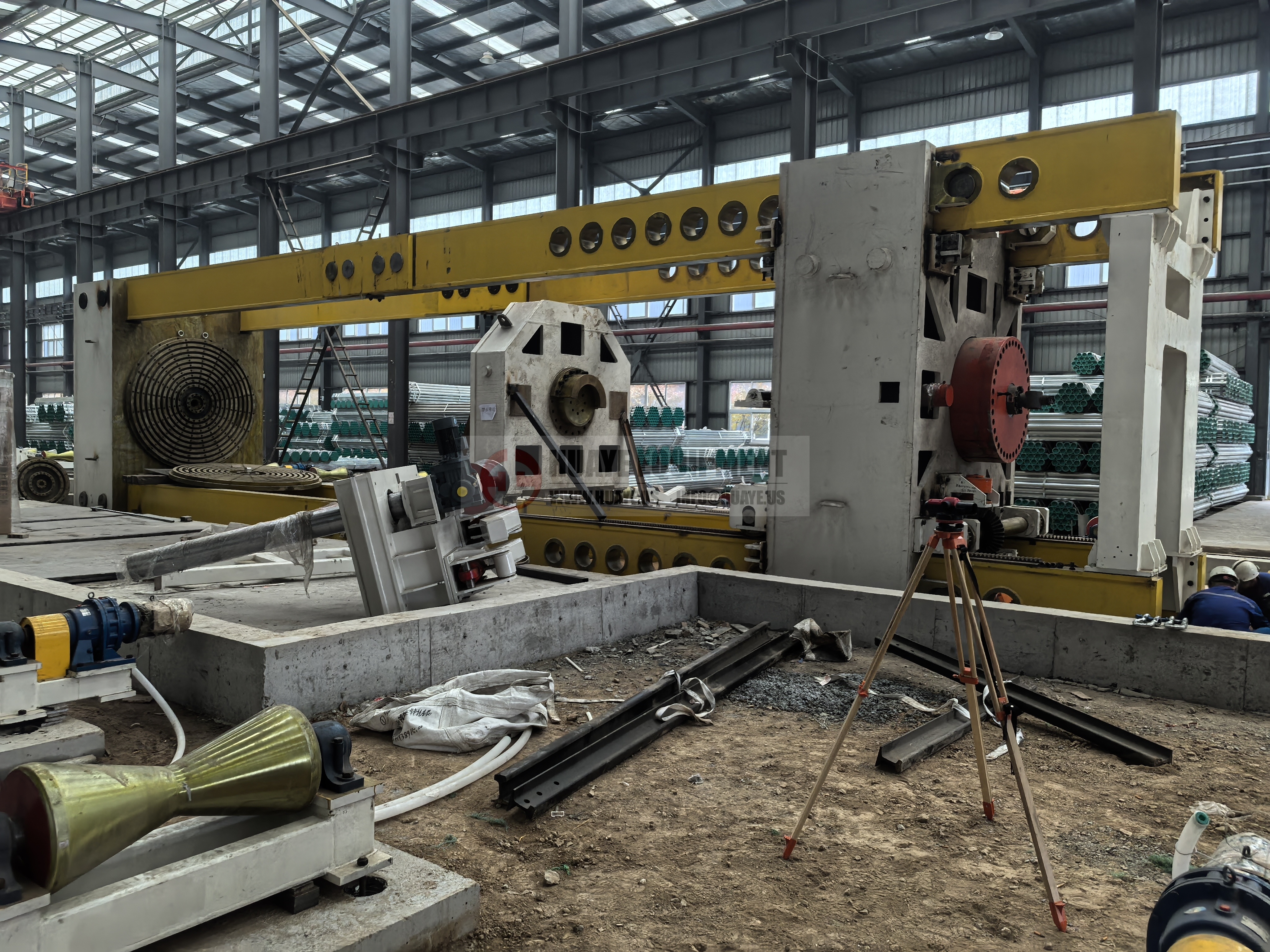

The 630mm and 2540mm full set of spiral welded pipe production lines are being installed in an orderly manner in Shaanxi. With the smooth progress of the project, the equipment installation has entered a critical stage. The project includes two high-performance spiral welded pipe production lines, which are used to produce steel pipes with a maximum diameter of 630mm and 2540mm respectively, to meet the needs of different diameter steel pipe markets.

In addition to the main equipment, the entire production line is also equipped with auxiliary equipment including pipe beveling machine, steel pipe hydo-tester and steel pipe transfer finishing area. The addition of these supporting equipment provides strong support for the efficient operation of the production line. The pipe beveling machine can accurately process the pipe end to ensure that the two ends of the steel pipe are smooth and convenient for subsequent welding and installation operations. The steel pipe hydo-tester conducts a strict hydraulic test on the formed steel pipe to effectively detect the sealing and pressure-bearing capacity of the pipe to ensure that each steel pipe can meet high-standard quality requirements. In addition, the steel pipe transfer finishing area is responsible for the production of the finished steel pipe transfer and other post-processing, to enhance the market competitiveness of the finished product.

Photos on Site:

Spiral welded pipe mill Section

At present, the equipment project of the whole set of spiral welded pipe production line is still in tense and orderly progress, and all installation will be completed soon. Commissioning work will be carried out later, and it is expected to be put into production soon. The Huaye project team will go all out to ensure that the production line can be put into production on time, help the local steel pipe industry upgrade, and enhance market competitiveness. At the same time, it also provides a strong guarantee for the infrastructure construction in the surrounding areas.

Want to know more information, welcome to contact us info@huaye.us!

Key words:

- All

- Product Management

- News

- Introduction

- Enterprise outlets

- FAQ

- Enterprise Video

- Enterprise Atlas

Related News

Working principle and application of spiral welded pipe machine

2024-09-09

Development direction of spiral welded pipe machine

2024-09-09

Matters needing attention when using spiral welded pipe machine

2024-09-09