Contact Us

Large diameter thin wall spiral welded pipe equipment

Key words:

Pipe welding equipment

Product category:

Product Details

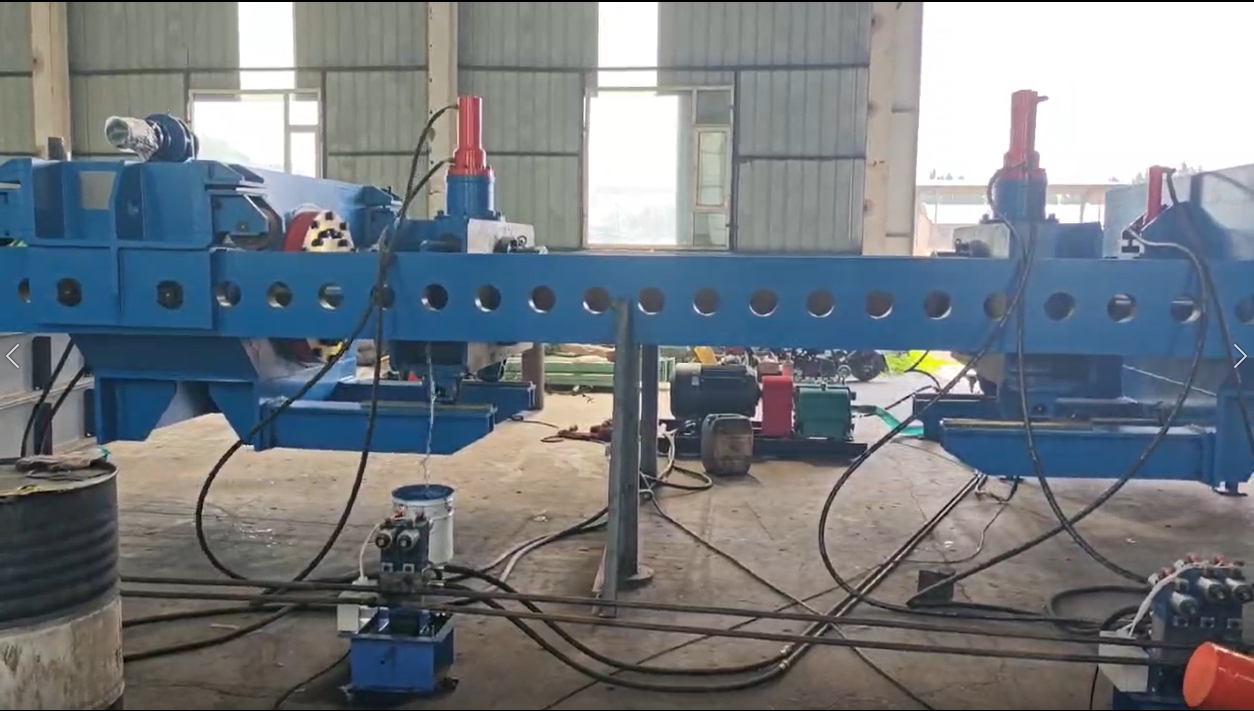

Large diameter thin wall spiral welded pipe equipment

Product Introduction

Large diameter and thin wall spiral welded pipe equipment is specially used to produce spiral welded pipe with large diameter but thin wall thickness. This kind of welded pipe is usually used in the field of conveying low pressure fluid, ventilation pipe, building structure and so on. Due to the thin wall of the welded pipe, special equipment and processes are required to ensure the welding quality and the overall strength of the product. The internal support is increased to avoid the deformation of the pipeline due to its own weight, and the price of the equipment is greatly reduced compared with the standard large-diameter spiral pipe unit.

Application areas

Large diameter thin-walled spiral welded pipe is widely used in the following fields due to its light weight, moderate strength and low manufacturing cost:

• Low pressure fluid transport: such as water, air and other transport pipeline.

Building structure: used for building support, enclosure structure, etc.

• Ventilation and exhaust systems: Piping used for ventilation and exhaust systems in industrial and commercial buildings.

Process flow

Coil preparation-uncoiling-straight head-pinch-leveling-shearing butt welding/cutting butt welding-flying welding vehicle-looper-pinch-disc shear/edge milling machine-delivery-pre-bending-guide plate-forming-internal welding-external welding-fixed-length cutting-pipe drop to pipe transport trolley-finished product collection

The spiral welded pipe production line is a mature unit with very competitive and technical characteristics in Huaye. The product specifications range from Φ25mm to 4000 Φmm, and are divided into general units and special customized units.

Specifications and models

| Model Series | Minimum pipe diameter | Maximum pipe diameter | Minimum wall thickness | Maximum wall thickness | Adapt to plate width | Maximum production capacity | Floor Area |

| mm | mm | mm | mm | mm | ton/year | m2 | |

| LH600 | 219-508 | 325-820 | 2-4 | 4-10 | 400-600 | 8000-12000 | 20X96 |

| LH800 | 219-508 | 406-1220 | 2-4 | 4-12 | 400-600 | 9000-17000 | 20X96 |

| LH1050 | 219-508 | 630-1620 | 2-4 | 4-14 | 450-1050 | 16000-23000 | 24X108 |

| LH1250 | 406-610 | 820-1620 | 3-6 | 8-18 | 500-1250 | 26000-35000 | 24X108 |

| LH1550 | 406-610 | 1420-3200 | 3-6 | 12-25.4 | 500-1550 | 36000-76000 | 26X125 |

| LH2000 | 406-610 | 2020-3200 | 4-6 | 20-25.4 | 1000-2000 | 77000-93000 | 30X180 |

The above models are for reference only and can be customized according to customer needs

Special customized production line

Huaye and Customers

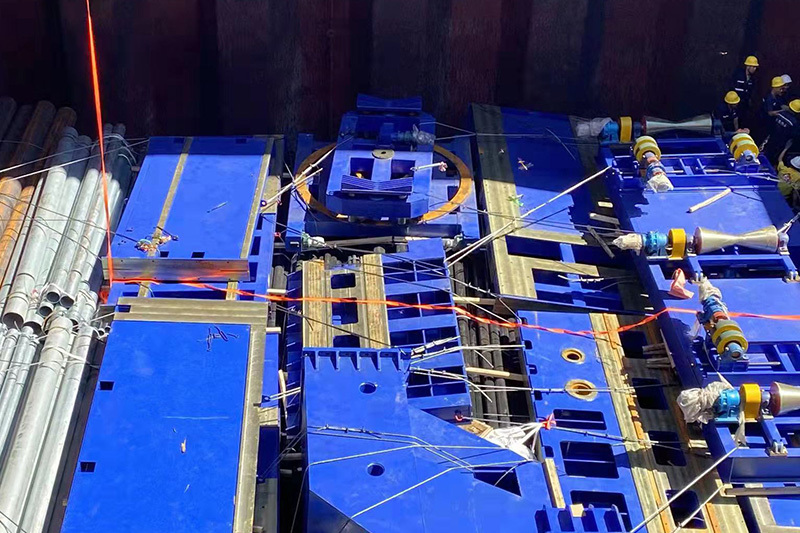

Shipping

Although the welded pipe equipment itself has a large volume and weight, it is basically modular. We will try our best to design each module into a standard container.

But there are always some special parts, no matter how to change the design also exceed the volume size of the container. At this time we will use frame containers or open top containers.

If there are too many overweight or oversized parts, we will also choose bulk carriers for shipment.

Product inquiry

* Please leave your contact information and we will contact you within 24 hours.