Contact Us

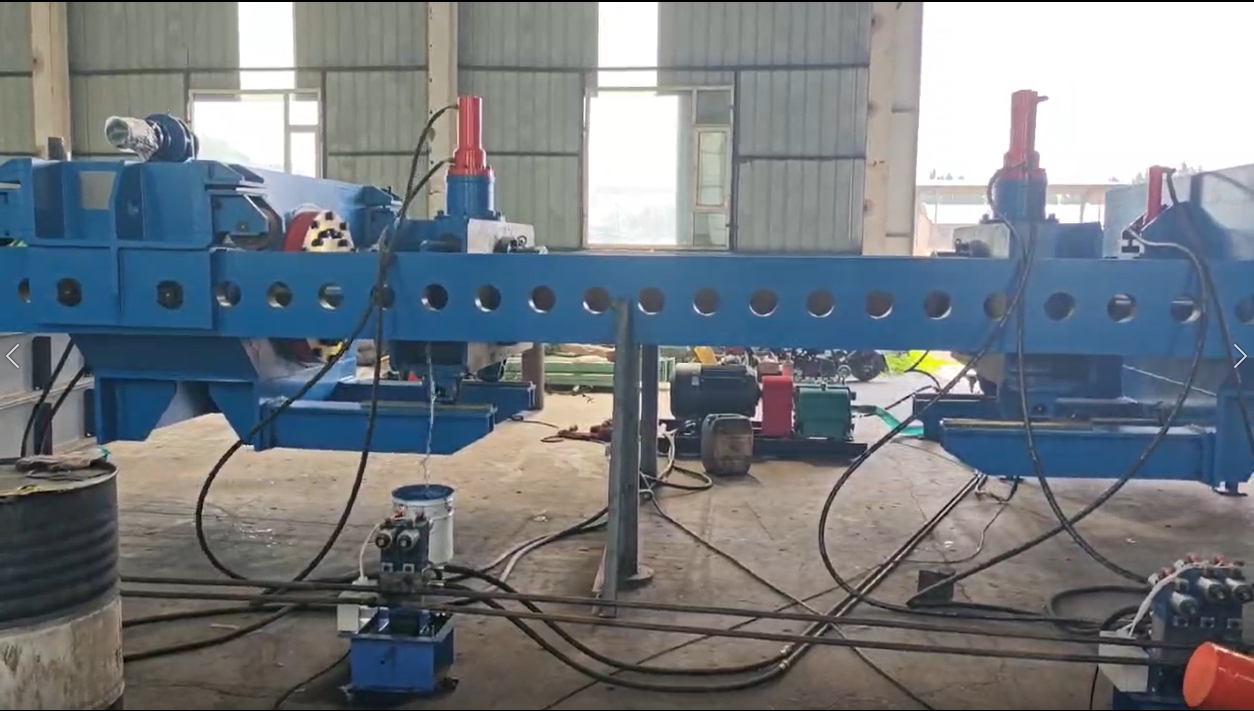

Punched Filter Spiral Welded Pipe Machine

Key words:

Pipe welding equipment

Product category:

Product Details

Punched Filter Spiral Welded Pipe Machine

Our company offers a customized Punched Filter Spiral Welded Pipe Machine. As a China - based supplier, we provide this machine. It's cheap yet of great quality for various needs.

Product Introduction

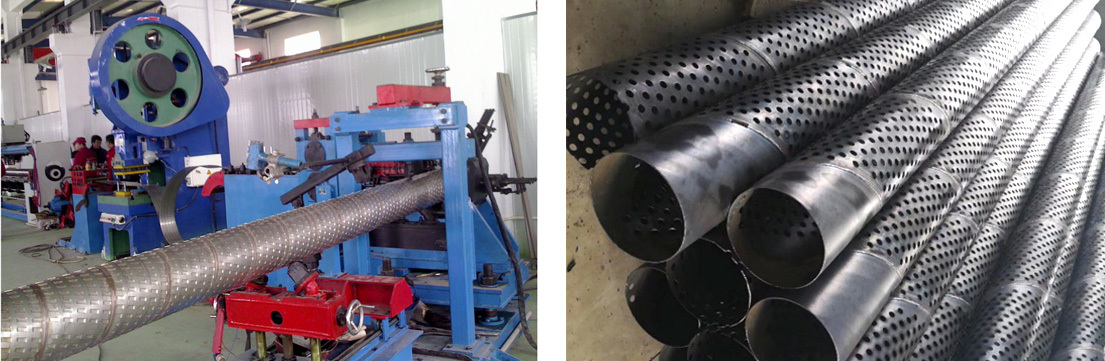

Punching spiral welded pipe equipment is a kind of equipment specially used for producing spiral welded pipe with holes. In the manufacturing process, this kind of equipment not only needs to complete the forming and welding of spiral welded pipes, but also needs to punch the pipes. Punched spiral welded pipe is widely used in drainage, ventilation, water filtration, environmental protection and other fields, especially suitable for piping systems that require ventilation, drainage or filtration functions.

The filter pipe mainly includes two types of round holes and bridge holes. By changing the mold design of the punch, the production of different hole types of filter pipes can be met.

Application areas

• Drainage system: used for underground drainage pipes and drainage trenches, which can effectively drain water.

• Ventilation systems: such as ventilation ducts and air filtration systems to provide good air circulation.

• Water filtration system: used for filtration devices in water treatment facilities to prevent impurities from entering the piping system.

• Environmental protection facilities: such as exhaust pipes and sewage treatment systems, using holes for ventilation and filtration.

Process flow

(The steel strip is lifted into the crane) Uncoiler → uncoiler → uncoiler → pinching and leveling → electric vertical roller alignment → steel plate punching → electric vertical roller alignment → steel strip head and plate tail butt joint → electric vertical roller alignment

The delivery machine feeds the steel plate → enters the guide plate device → manual vertical roller alignment → forming and sizing of the steel pipe of the forming machine → internal welding → rear axle roller → external welding → steel pipe cutting → steel pipe output → pipe unloading

The spiral welded pipe production line is a mature unit with very competitive and technical characteristics in Huaye. The product specifications range from Φ25mm to 4000 Φmm, and are divided into general units and special customized units.

Specifications and models

| Model Series | Minimum pipe diameter | Maximum pipe diameter | Minimum wall thickness | Maximum wall thickness | Adapt to plate width | Maximum production capacity | Floor Area |

| mm | mm | mm | mm | mm | ton/year | m2 | |

| LH600 | 219-508 | 325-820 | 2-4 | 4-10 | 400-600 | 8000-12000 | 20X96 |

| LH800 | 219-508 | 406-1220 | 2-4 | 4-12 | 400-600 | 9000-17000 | 20X96 |

| LH1050 | 219-508 | 630-1620 | 2-4 | 4-14 | 450-1050 | 16000-23000 | 24X108 |

| LH1250 | 406-610 | 820-1620 | 3-6 | 8-18 | 500-1250 | 26000-35000 | 24X108 |

| LH1550 | 406-610 | 1420-3200 | 3-6 | 12-25.4 | 500-1550 | 36000-76000 | 26X125 |

| LH2000 | 406-610 | 2020-3200 | 4-6 | 20-25.4 | 1000-2000 | 77000-93000 | 30X180 |

The above models are for reference only and can be customized according to customer needs

Special customized production line

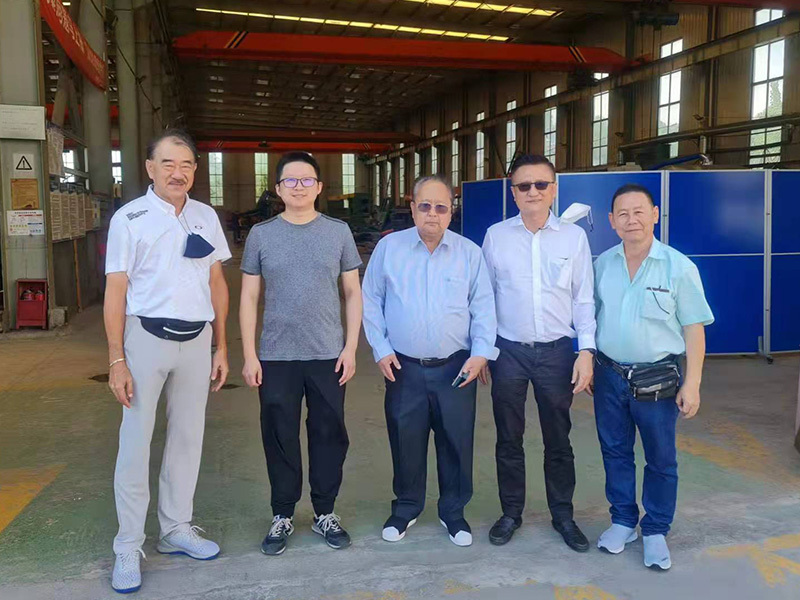

Huaye and Customers

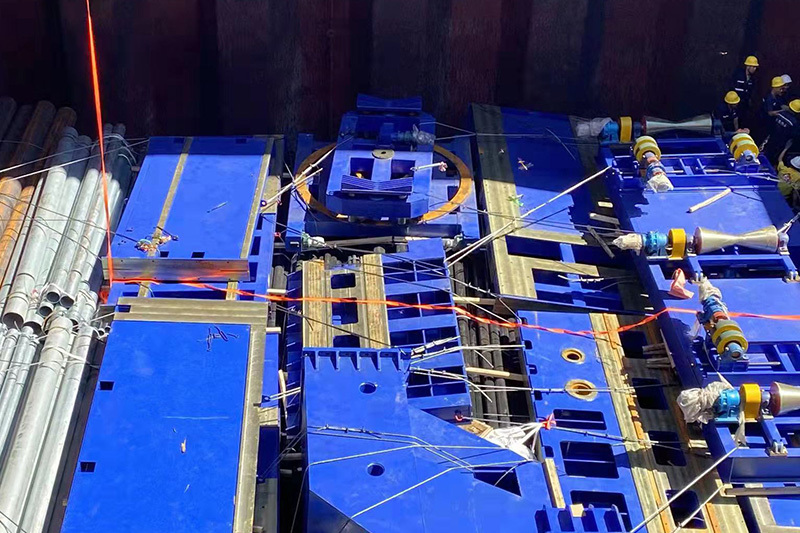

Shipping

Although the welded pipe equipment itself has a large volume and weight, it is basically modular. We will try our best to design each module into a standard container.

But there are always some special parts, no matter how to change the design also exceed the volume size of the container. At this time we will use frame containers or open top containers.

If there are too many overweight or oversized parts, we will also choose bulk carriers for shipment.

Previous:

Product inquiry

* Please leave your contact information and we will contact you within 24 hours.