Contact Us

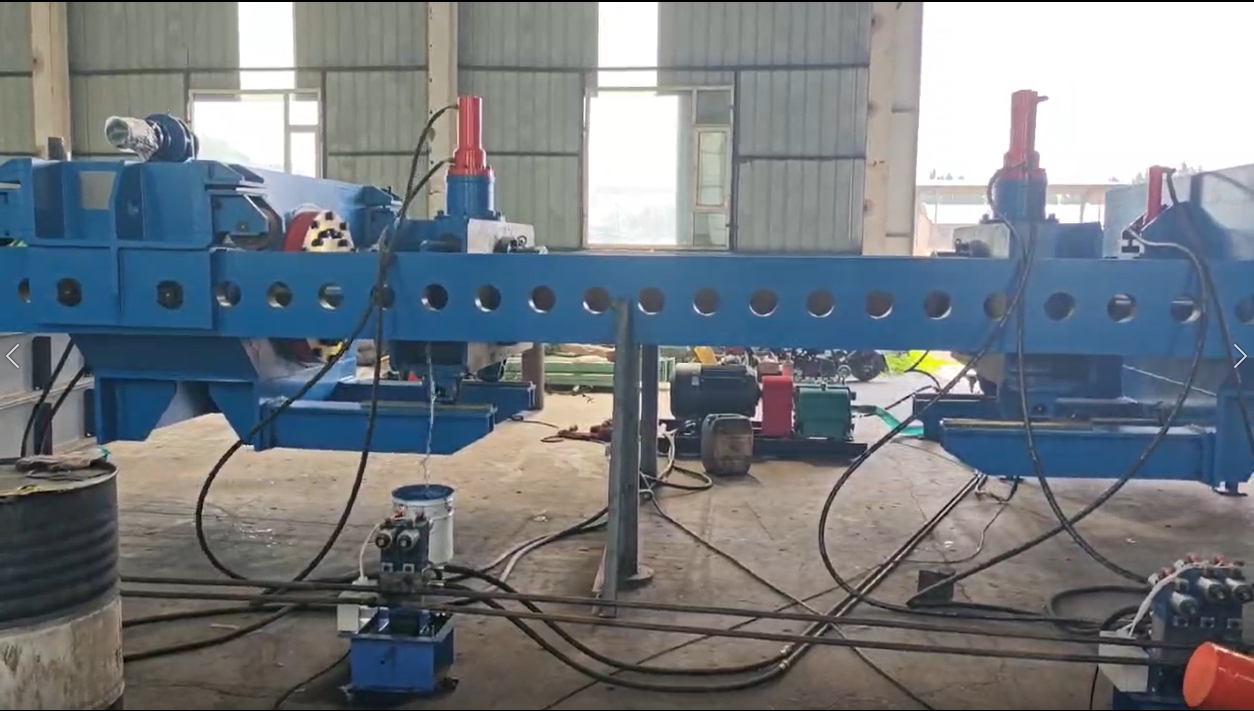

Rear Swing Type Spiral Welded Pipe Machine

Key words:

best Rear Swing Type Spiral Welded Pipe Machine brands

Pipe welding equipment

Product category:

Product Details

Rear Swing Type Spiral Welded Pipe Machine

Product Introduction

The rear swing type is one of the machine forms of spiral welded pipe machine. Through the adjustment of the rear axle that can rotate around the forming rotation point, the process preparation section equipment is installed on the flying welding vehicle, which can realize continuous and uninterrupted production. Commonly used in oil, natural gas, water transportation, building structures and other fields of pipeline production. Such equipment produces spiral welded pipes with high strength and pressure resistance by winding the steel strip into a spiral shape and welding at the gap.

Main advantages

High production efficiency: continuous production, this equipment usually has a high degree of automation, high production efficiency, suitable for mass production.

• Wide applicability: It is suitable for producing spiral welded pipes of different diameters and wall thicknesses, with greater adaptability.

Process flow

Coil preparation-uncoiling-straight head-pinch-leveling-shearing butt welding/cutting butt welding-flying welding vehicle-looper-pinch-disc shear/edge milling machine-delivery-pre-bending-guide plate-forming-internal welding-external welding-fixed-length cutting-pipe drop to pipe transport trolley-finished product collection

The spiral welded pipe production line is a mature unit with very competitive and technical characteristics in Huaye. The product specifications range from Φ25mm to 4000 Φmm, and are divided into general units and special customized units.

Specifications and models

| Model Series | Minimum pipe diameter | Maximum pipe diameter | Minimum wall thickness | Maximum wall thickness | Adapt to plate width | Maximum production capacity | Floor Area |

| mm | mm | mm | mm | mm | ton/year | m2 | |

| LH600 | 219-508 | 325-820 | 2-4 | 4-10 | 400-600 | 8000-12000 | 20X96 |

| LH800 | 219-508 | 406-1220 | 2-4 | 4-12 | 400-600 | 9000-17000 | 20X96 |

| LH1050 | 219-508 | 630-1620 | 2-4 | 4-14 | 450-1050 | 16000-23000 | 24X108 |

| LH1250 | 406-610 | 820-1620 | 3-6 | 8-18 | 500-1250 | 26000-35000 | 24X108 |

| LH1550 | 406-610 | 1420-3200 | 3-6 | 12-25.4 | 500-1550 | 36000-76000 | 26X125 |

| LH2000 | 406-610 | 2020-3200 | 4-6 | 20-25.4 | 1000-2000 | 77000-93000 | 30X180 |

The above models are for reference only and can be customized according to customer needs

Special customized production line

Huaye and Customers

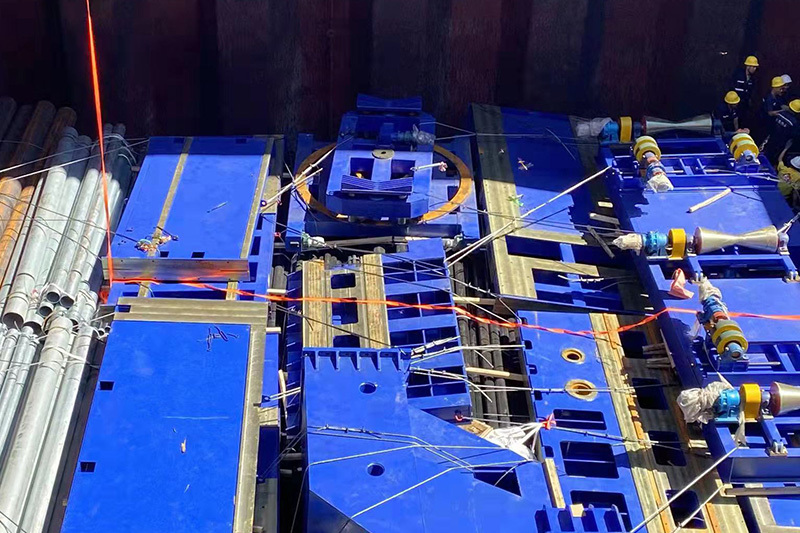

Shipping

Although the welded pipe equipment itself has a large volume and weight, it is basically modular. We will try our best to design each module into a standard container.

But there are always some special parts, no matter how to change the design also exceed the volume size of the container. At this time we will use frame containers or open top containers.

If there are too many overweight or oversized parts, we will also choose bulk carriers for shipment.

Product inquiry

* Please leave your contact information and we will contact you within 24 hours.