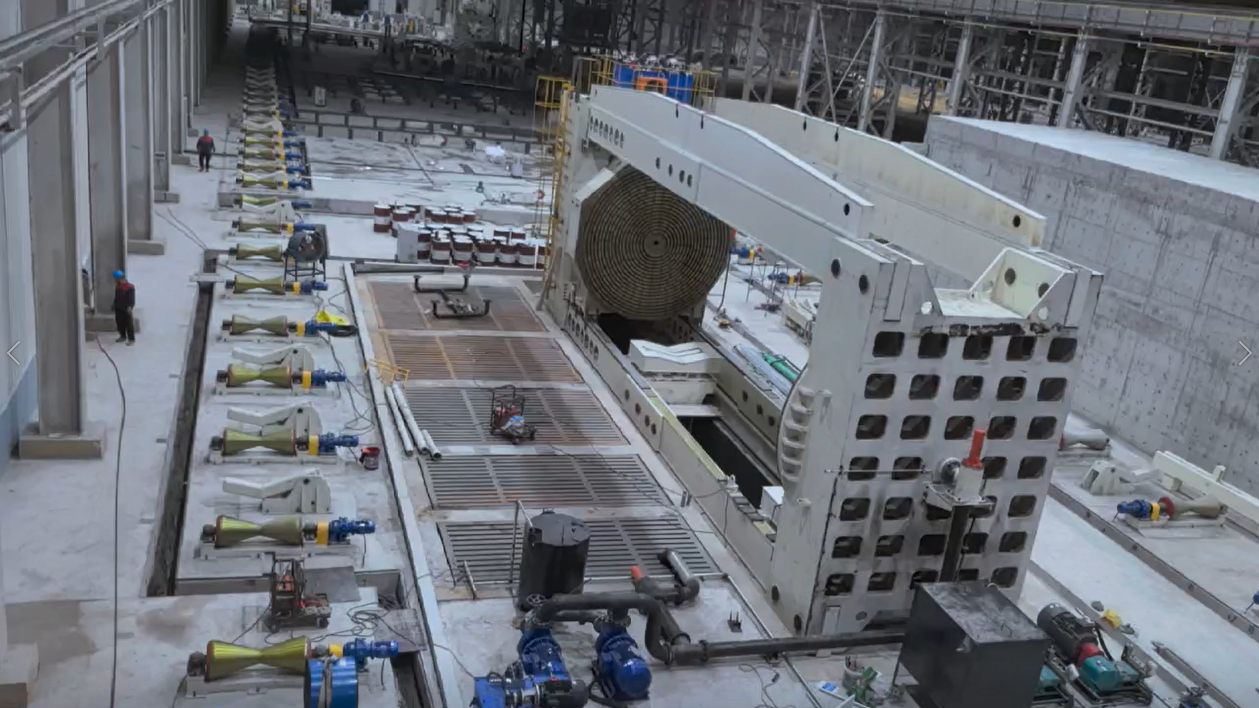

Installation Site of Two Spiral Pipe Production Lines Φ820 and Φ4220

24 Sep,2025

These are two brand-new spiral welded pipe production lines recently introduced by Huaye in Jiangsu,China, capable of handling pipe diameters ranging from Φ219 to Φ4220 mm. The installation of these two new lines is nearing completion and they will soon be put into operation, significantly boosting customers' production capacity. This milestone also underscores Huaye Heavy Industry's growing expertise—particularly in the manufacturing of large-diameter spiral welded pipes—enabling us to better meet the diverse needs of our clients. Whether it’s enhancing quality control or increasing output, we’re committed to delivering products that are not only more competitive but also backed by even more reliable service for our valued customers.

D820 × 14 mm Spiral Welded Pipe Mill

Plate width: 450 – 1050 mm

Pipe diameter: Φ219 – Φ820 mm

Wall thickness: 5 – 14 mm

Pipe length: 6–13 m

D4220×28 mm Spiral Welded Pipe Mill

Plate width: max. 2000 mm

Pipe diameter: Φ820 – Φ4220 mm

Wall thickness: 8 – 28 mm

Pipe length: 6–13 m

From setting up the infrastructure to installing and fine-tuning each piece of equipment, every step has been meticulously crafted with the wisdom and hard work of countless engineers and technicians. Each move is aimed at achieving ultimate precision and efficiency, all in pursuit of delivering high-quality, highly profitable, and cost-effective outcomes in future production.

We firmly believe that continuous technological innovation and ongoing upgrades to our production lines will undoubtedly fuel the company’s sustained growth. Moving forward, we will remain committed to the philosophy of "striving for excellence and driving innovation," constantly elevating our manufacturing processes to deliver even more high-quality products that contribute positively to our nation and society.

Welcome to contact us info@huaye.us for more details!

Key words:

- All

- Product Management

- News

- Introduction

- Enterprise outlets

- FAQ

- Enterprise Video

- Enterprise Atlas

Related News

Choosing the Right Pipe Prepping Machine: Essential Factors to Consider

2025-12-23

Essential Insights into Pipe Prepping Machines for Precision Manufacturing

2025-12-18

From Raw to Ready: How Pipe Prepping Machines Transform Your Workflow

2025-12-13