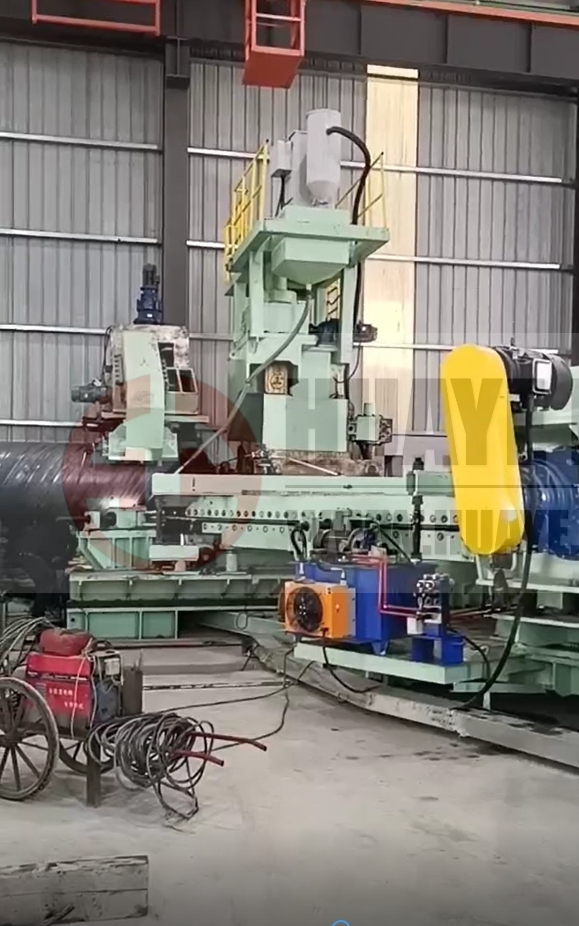

Φ1640×18 mm Full Set of API Spiral Pipe Production Line in Gansu, China

18 Aug,2025

The Φ1640 × (5-18) mm Full API Standard Spiral Pipe Production Line, entirely undertaken by Huaye, has been successfully designed, manufactured, installed, and commissioned in Gansu,China.

The production line includes all equipment required for the production of API standard spiral welded pipes, including:

- Spiral Pipe Mill

- End Facing and Beveling Machine

- Hydrostatic Tester

- X-ray Inspection Equipment

- Ultrasonic Testing (UT) System

- Slag Removal Machine

- Pipe Expander

- T-Seam Repair Welding Machine

- Pipe Conveyor System

Machine Specifications:

- Pipe Width : 750 – 1500 mm

- Pipe O.D. : 325 – 1640 mm

- Pipe Thickness : 5 – 18 mm

- Pipe Length : 8-12 m

Photos On-Site:

The successful commissioning and upcoming production of the Gansu Φ1640×18 mm full set API spiral welded pipe production line marks a significant milestone for Huaye Heavy Industry in the field of high-end oil and gas pipeline equipment manufacturing. As a globally recognized standard in the petroleum and natural gas industry, the API (American Petroleum Institute) certification ensures that this production line not only meets the growing domestic demand for energy infrastructure but also enhances the competitiveness of Chinese steel pipe products in the international market. With its deep expertise and technological innovation in heavy equipment manufacturing, Huaye Heavy Industry guarantees the efficient and intelligent operation of this production line. From raw material coils to finished welded pipes, every step follows the strict API standards, ensuring product quality that is both safe and reliable.

Contact info@huaye.us for more information!

Key words:

- All

- Product Management

- News

- Introduction

- Enterprise outlets

- FAQ

- Enterprise Video

- Enterprise Atlas

Related News

Understanding Tube Beveling Machines: Essential Knowledge for Manufacturing Professionals

2025-12-30

Choosing the Right Pipe Prepping Machine: Essential Factors to Consider

2025-12-23

Essential Insights into Pipe Prepping Machines for Precision Manufacturing

2025-12-18