The role of spiral welded pipe equipment delivery roller leveling roller?

12 Nov,2024

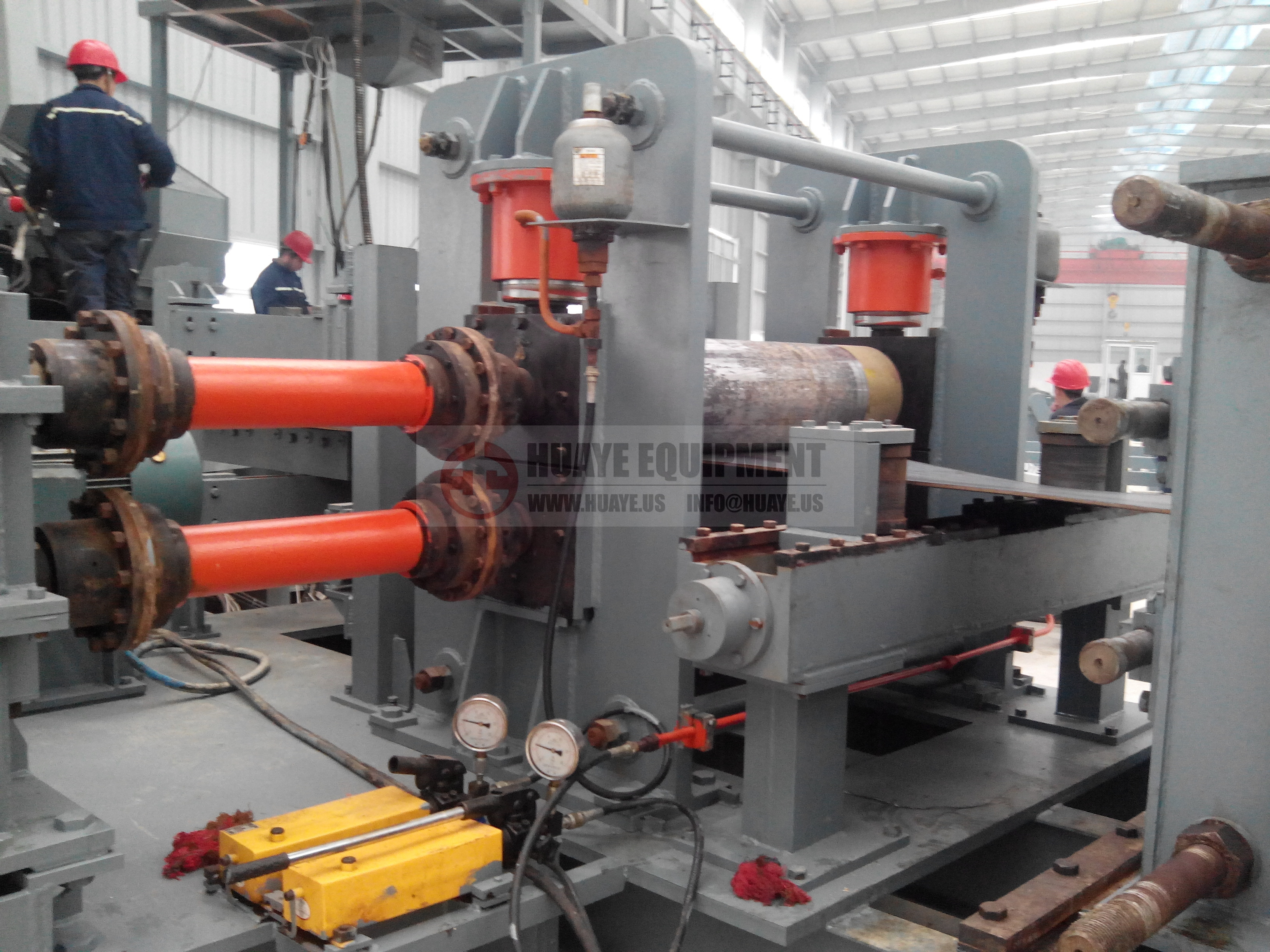

The delivery roller and the leveling roller in the spiral welded pipe equipment have different functions, and they play a vital role in the production process of spiral welded pipe.

The role of the delivery roller: The delivery roller is mainly used to transport the steel strip (or steel plate) to the next process at a set speed to ensure the smooth transmission of the steel strip throughout the production process. They are usually installed at the feed end of the equipment or between individual processes.

The role of the leveling roller: The leveling roller is used for the correction of the steel strip. The purpose is to eliminate the bending, warping or unevenness of the steel strip during the production process, and make the surface more straight, thereby improving the production accuracy and quality of the welded pipe. The leveling roller is usually used after the steel strip has undergone some preliminary forming process. Its role includes:

Straightening steel strip: Remove the wavy or curved shape of the steel strip to make it more flat.

Improve welding quality: If the surface of the steel strip is uneven, it will affect the welding quality. The leveling roller straightens the steel strip to ensure that the contact surface of the welding area is smooth, which helps to improve the firmness of the welded joint.

Ensure the shape of the pipeline: the flatness of the steel strip directly affects the forming process of the welded pipe. The leveling roller ensures that the steel strip enters the forming equipment after being leveled, which helps to produce welded pipes with more accurate specifications and uniform appearance.

In general, the delivery roller is mainly responsible for the transportation of the steel belt, while the leveling roller is responsible for the correction and smoothing of the steel belt. The two work together to ensure the efficient operation and product quality of the spiral welded pipe production line.

Key words:

- All

- Product Management

- News

- Introduction

- Enterprise outlets

- FAQ

- Enterprise Video

- Enterprise Atlas

Related News

Essential Insights into Pipe Prepping Machines: A Comprehensive Guide

2025-12-08

How to Ensure Your Pipe Welding Equipment Meets Industry Standards

2025-12-03

Essential Guide to Pipe Welding Equipment for Efficient Manufacturing

2025-11-28