Complete Spiral Pipe Plant Now Operational! Congratulations to Huaye on a Major Project Success.

27 Feb,2025

Congratulations to Huaye for successfully completing a major project, with the full set of spiral welded pipes launched in Shaanxi, starting production!

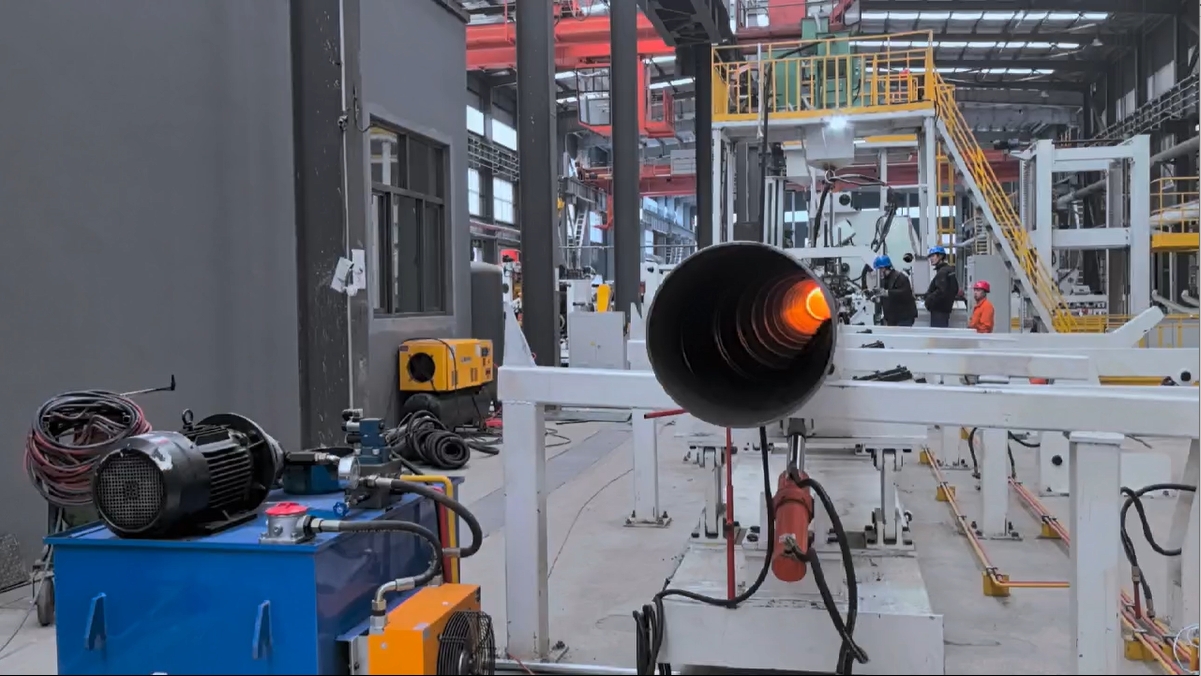

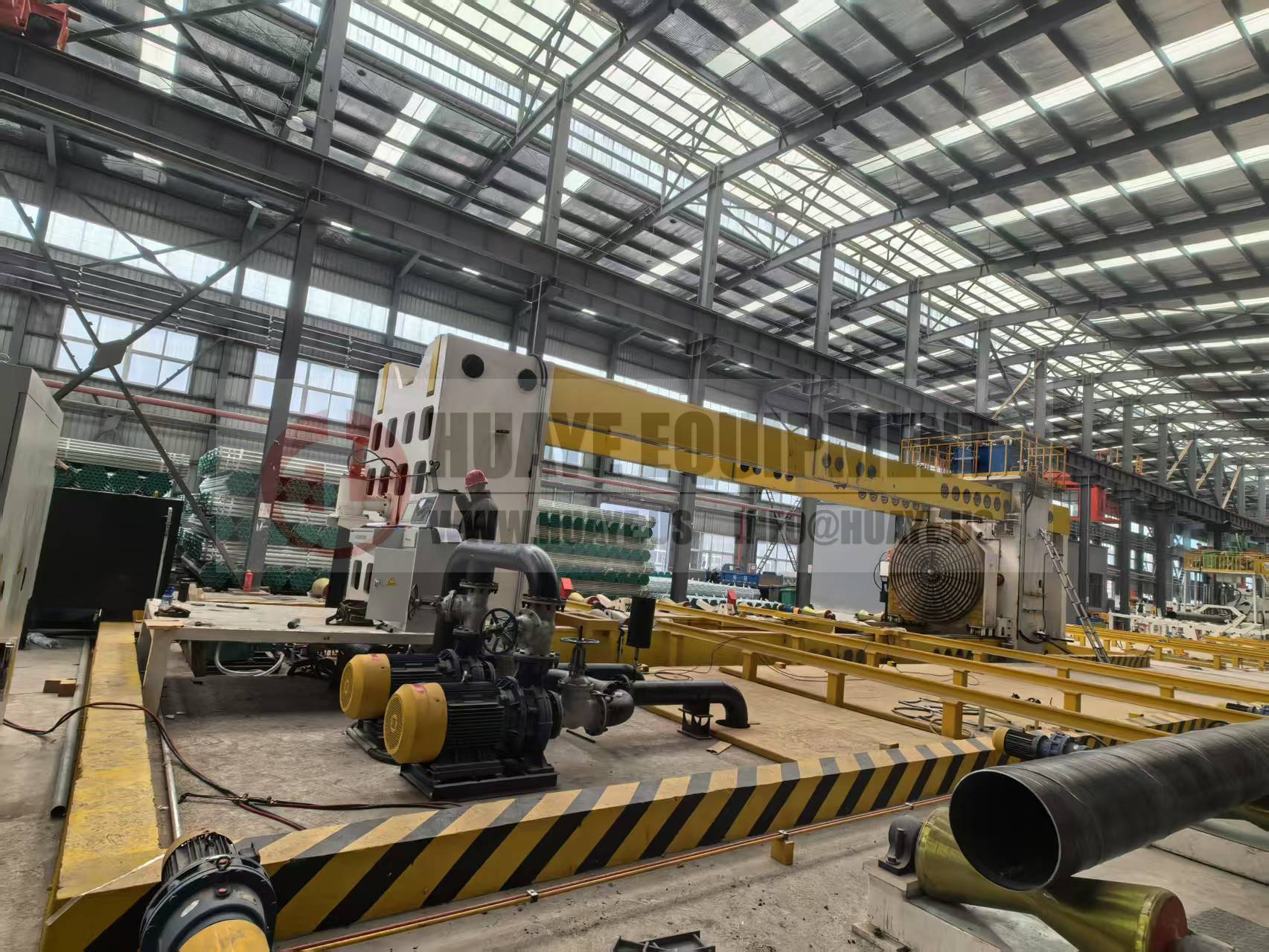

This project includes two high-efficiency spiral welded pipe production lines, used to produce steel pipes with diameters of up to 630mm and 2540mm, meeting the needs of different caliber steel pipe markets. In addition to the main equipment, the entire production line is also equipped with auxiliary equipment including a flat-end beveling machine, a steel pipe hydraulic testing machine, and a steel pipe transfer finishing area. The addition of these supporting devices provides strong support for the efficient operation of the production line. The flat-end beveling machine can precisely process the pipe ends, ensuring that both ends of the steel pipe are flat and smooth, facilitating subsequent welding and installation operations. The steel pipe hydraulic testing machine conducts strict water pressure tests on the formed steel pipes, effectively detecting the sealing and pressure-bearing capacity of the pipes, ensuring that each steel pipe meets high-quality standards. In addition, the steel pipe transfer finishing area is responsible for the post-processing of completed steel pipes, enhancing the market competitiveness of the finished products.

Complete spiral welded pipe factory

Project site image:

Two sets of spiral welded pipe main machines

End Facing and beveling machines

Hydrostatic testing machine

Steel pipe transfer finishing area equipment

The new production of this factory not only marks a significant breakthrough in technological innovation and capacity expansion but also injects strong momentum into the development of infrastructure construction in the region and even the whole country. By adopting advanced spiral welding technology and automated production lines, the Shaanxi spiral welded pipe factory has significantly improved production efficiency while ensuring excellent product quality, effectively shortening the product delivery cycle, and better meeting the growing market demand for high-quality welded pipes. The initiation of this efficient production not only showcases the strength of "Made in China" but also serves as a vivid practice of the enterprise's active response to the national call for green low-carbon and intelligent manufacturing, indicating that the Shaanxi spiral welded pipe factory will lead the industry forward with a more vigorous posture in future development, contributing to the economic and social development of our country.

Contact Us info@huaye.us to learn more!

Key words:

- All

- Product Management

- News

- Introduction

- Enterprise outlets

- FAQ

- Enterprise Video

- Enterprise Atlas

Related News

Working principle and application of spiral welded pipe machine

2024-09-09

Development direction of spiral welded pipe machine

2024-09-09

Matters needing attention when using spiral welded pipe machine

2024-09-09