Stable Pipe Production of Φ2540mm Spiral Pipe Mill in China

29 Sep,2025

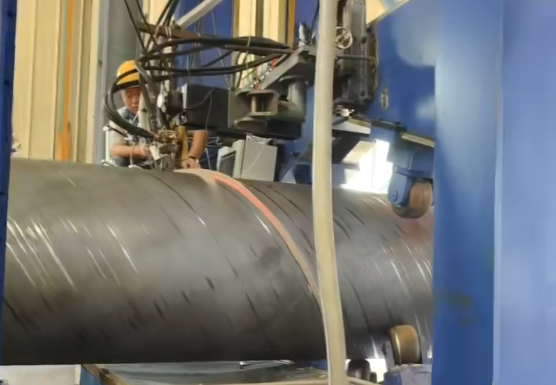

At the Jiangsu production site, the 2540 spiral pipe mill designed and manufactured by Huaye is steadily producing pipes. The equipment operates with high efficiency, and the entire production process flows seamlessly! These spiral welded pipes will be widely used in critical sectors such as oil, natural gas, and urban water supply.

As a leading manufacturer of heavy industrial equipment, Huaye Heavy Industry has always been committed to providing customers with high-quality, highly reliable pipeline production solutions. The successful operation of the 2540 spiral pipe mill in Jiangsu not only highlights our cutting-edge advantages in technology development but also once again underscores our industry-leading position in the field of spiral welded pipe equipment.

Equipment parameters:

Steel coil parameters:

Outer diameter O.D.: Φ1200–1500 mm

Inner diameter I.D.: Φ610–760 mm

Board width: 600–1550 mm

Plate thickness: 6–20 mm

Material: Q235, Q355 (≤12mm)

Product specifications:

Steel pipe outer diameter O.D.: Φ508–2540 mm

Wall thickness: 6–20 mm

Pipe length: 8–12 m

Production Site:

In the future, Huaye Heavy Industry will continue to dedicate itself to technological innovation, relentlessly enhancing product quality and production efficiency, and striving to deliver customers more efficient, environmentally friendly, and intelligent welded pipe equipment solutions. We firmly believe that with ongoing technological breakthroughs and a comprehensive service system in place, Huaye Heavy Industry will steadily advance within the spiral welded pipe industry, providing global customers with even more high-quality, high-performance products and services.

If you're interested in similar equipment, feel free to contact us directly!

Key words:

- All

- Product Management

- News

- Introduction

- Enterprise outlets

- FAQ

- Enterprise Video

- Enterprise Atlas

Related News

Choosing the Right Pipe Prepping Machine: Essential Factors to Consider

2025-12-23

Essential Insights into Pipe Prepping Machines for Precision Manufacturing

2025-12-18

From Raw to Ready: How Pipe Prepping Machines Transform Your Workflow

2025-12-13