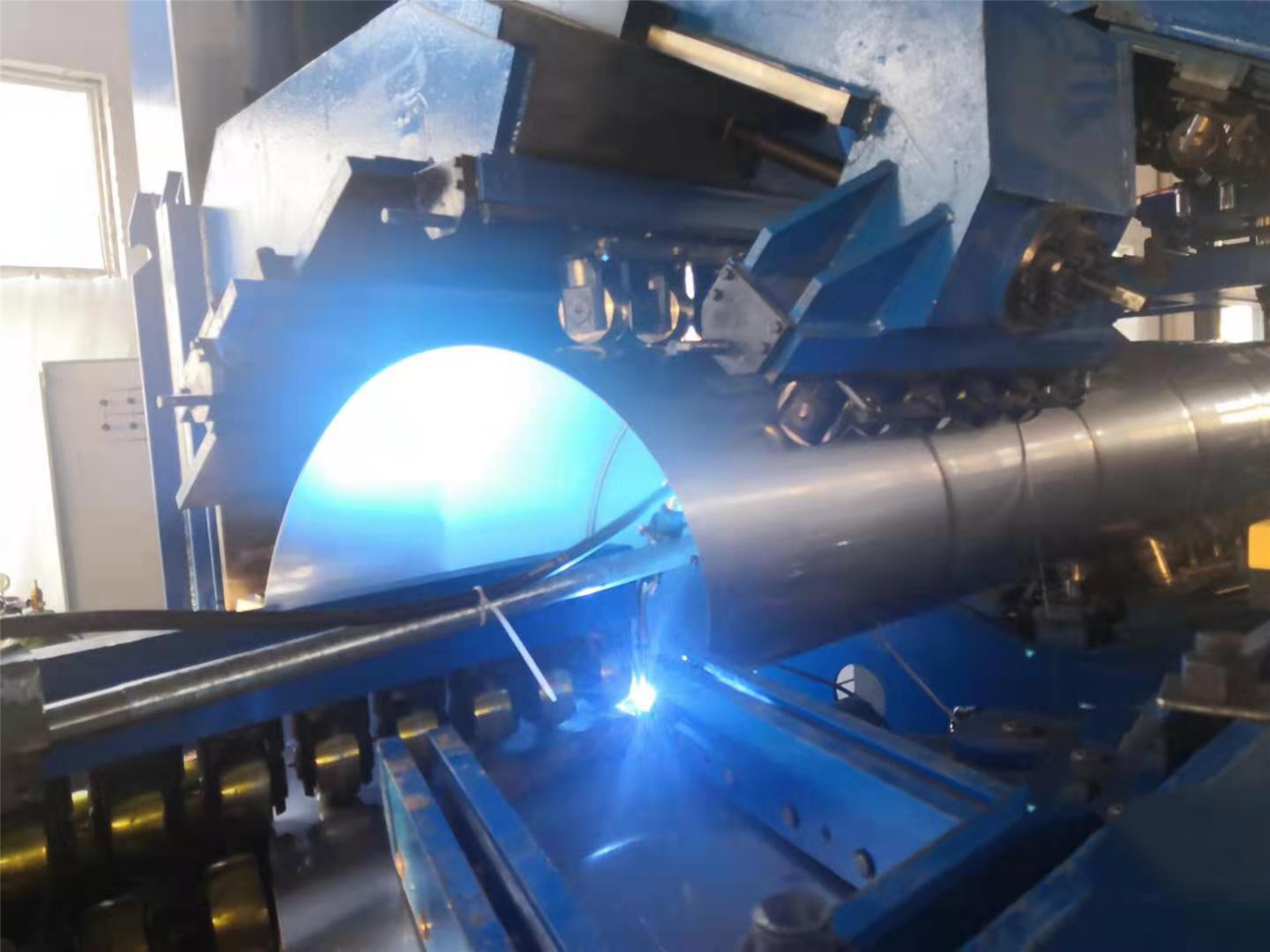

Huaye - 1500×3mm stainless steel spiral pipe machine

03 Jul,2025

This is an independently developed 1500×3mm stainless steel spiral welded pipe equipment ,specially designed for the efficient and precise production of thin-walled stainless steel pipes. The equipment supports continuous forming and automatic welding with a maximum bandwidth of 1500mm and a plate thickness of 3mm, and has significant advantages such as intelligent operation, low energy consumption, stable finished pipe diameter, and high weld quality. Argon arc welding method is used for pipe welding. With special designed forming cage and support device, the machine can form large diameter pipes with thin wall without any deformation.

Equipment Specifications:

Pipe diameter: Φ600mm - Φ1500mm

Pipe wall thickness: 1.5mm-3 mm

Pipe length: 8-12m

Core advantages:

✔ High-precision welding: Using advanced spiral welding technology to ensure uniform and firm welds with strong sealing, suitable for high-pressure and corrosion-resistant environments.

✔ High-quality stainless steel material: Using 304/316 stainless steel raw materials, acid and alkali resistant, rust-proof, and long service life.

✔ Automated production: Intelligent control system, realizing efficient and stable production, reducing labor costs, and improving production capacity.

✔ Wide application: Suitable for petroleum, chemical, water supply, construction and other fields, meeting diverse pipeline needs. 。

If you are interested in similar equipment, please feel free to contact us info@huaye.us!

Key words:

- All

- Product Management

- News

- Introduction

- Enterprise outlets

- FAQ

- Enterprise Video

- Enterprise Atlas

Related News

Cost vs. Quality: Investing in an Automatic Beveling Machine

2025-09-19

Unlocking Efficiency: The Advantages of Automatic Beveling Machines in Manufacturing

2025-09-14

The Essential Guide to Choosing a Pipe Roller Machine for Welding in Your Workshop

2025-09-11