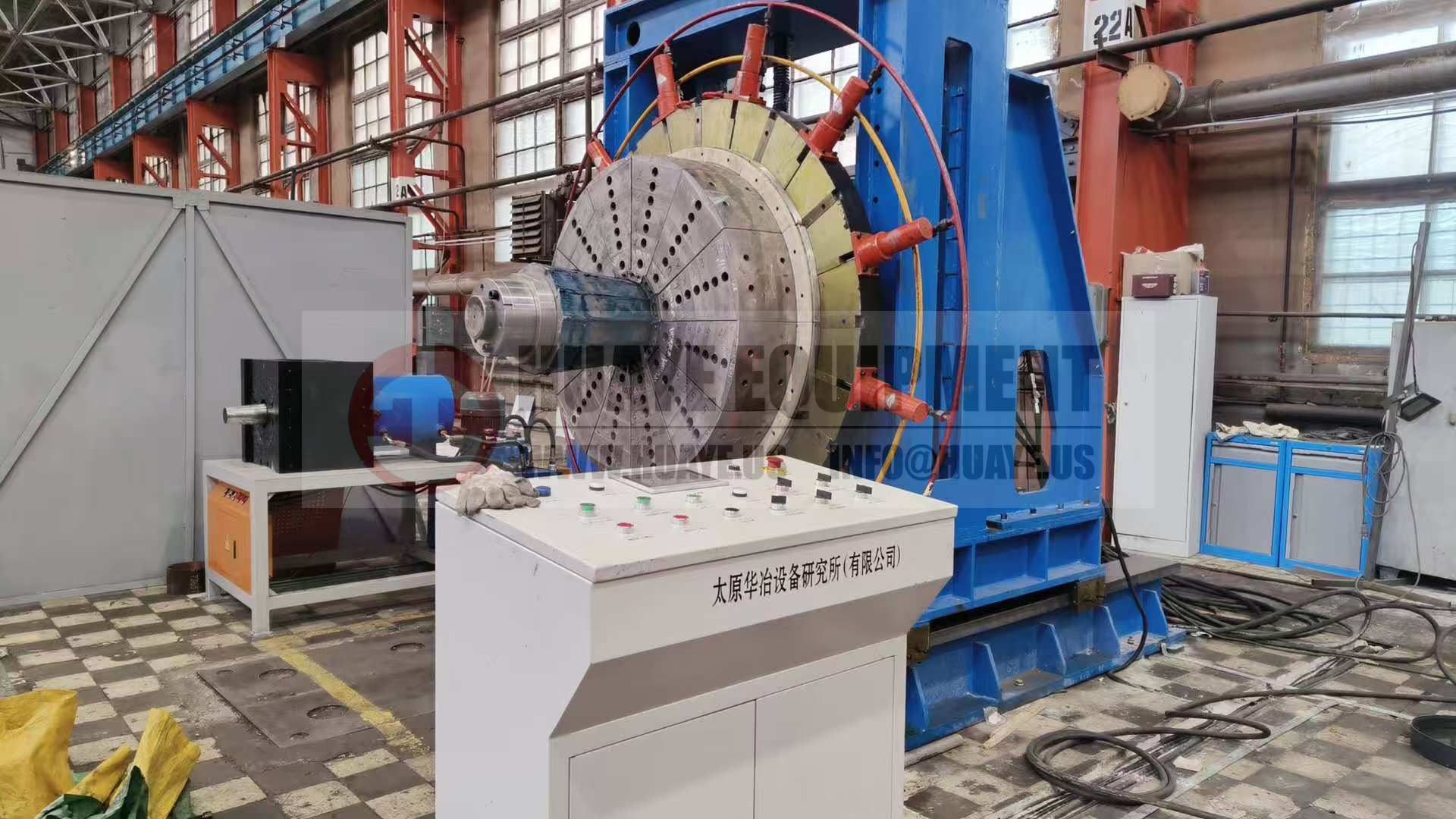

Huaye Heavy Industry Manufacturing: 1420 Expanding Machine Russian Debugging Successfully Completed

17 Mar,2025

Thanks to the joint efforts of the Huaye Heavy Industry team and the close cooperation of the Russian customer, the on-site commissioning of the 1420 expander has been successfully completed. During the commissioning, the team overcame multiple challenges, including language communication, cultural differences, and the complex on-site environment. Through fine-tuning and continuous optimization, the team ensured that all performance indicators of the expander met the expected standards, providing solid technical support for the Russian customer's production line upgrade.

Expander Parameters:

Expansion method: Mechanical expansion

Expandable pipe diameter range: φ529~φ1420 mm

Expandable pipe wall thickness range: 4-12mm

Expandable pipe length range: 6-12 m

The success of this cooperation has not only deepened Huaye Heavy Industry's connection with the international market, but also laid a solid foundation for future cooperation, demonstrating the competitiveness and influence of "Made in China" on the global industrial stage. In the future, Huaye Heavy Industry will continue to be committed to technological innovation and service quality improvement to provide global customers with more efficient and reliable equipment solutions.

Key words:

- All

- Product Management

- News

- Introduction

- Enterprise outlets

- FAQ

- Enterprise Video

- Enterprise Atlas

Related News

Why Every Workshop Needs a Steel Beveling Machine for Precision Cutting

2026-02-14

2026-02-11

Hydrostatic Tester of Spiral Welded Pipes: Ensuring Safety and Performance in Pipeline Systems

2026-02-11