Contact Us

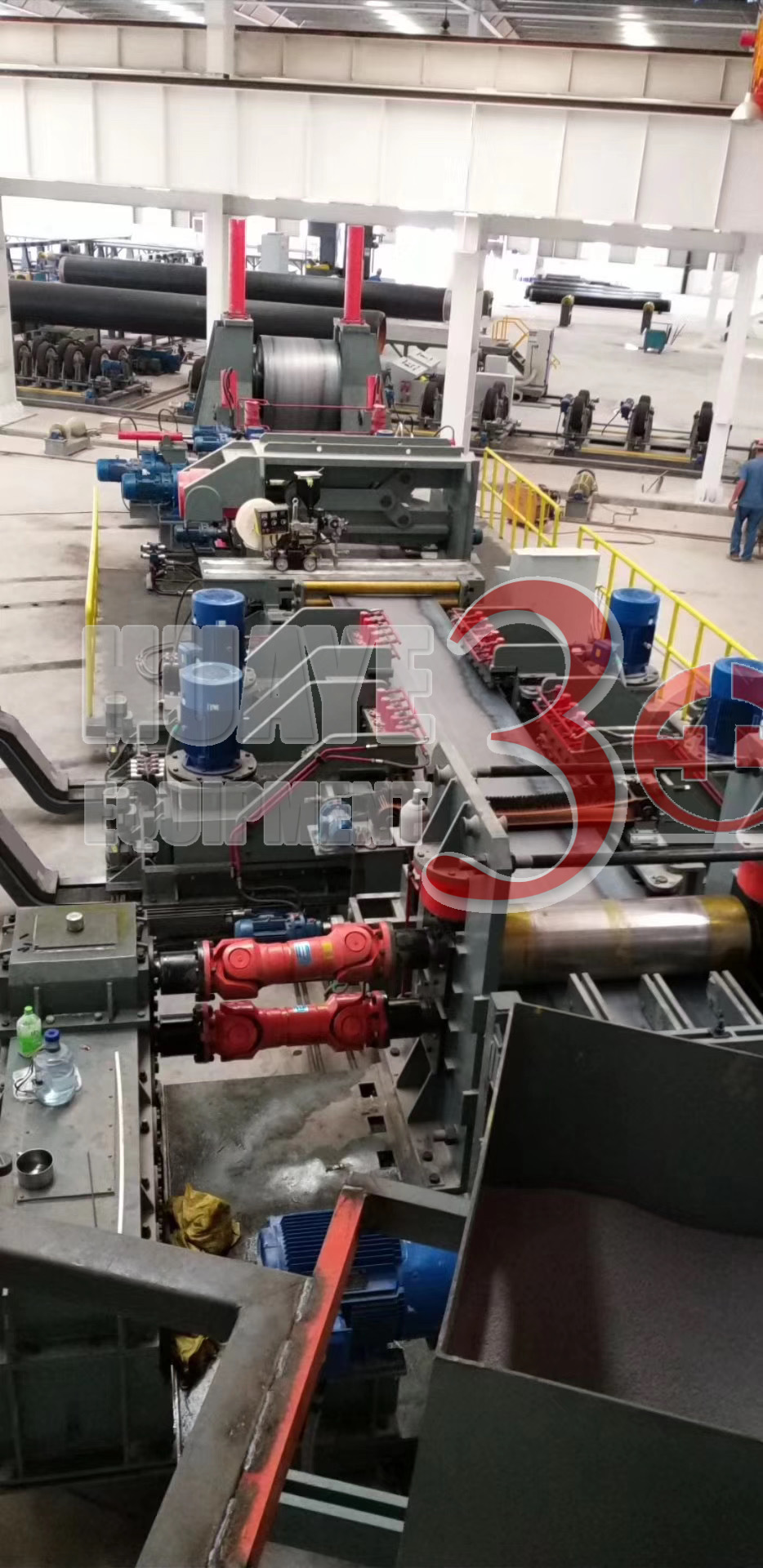

Efficient Edge Miller Production—Spiral Pipe Line

22 May,2025

Huaye Edge Miller of spiral welded pipe equipment has now entered the mass production stage! A variety of models of milling machine fully open orders to meet your diversified production needs. Whether it is standard specifications or customized solutions, Huaye can respond to your needs one by one and help your production line to double the efficiency!

Edge milling machine, it's an indispensable key equipment in the process of producing spiral welded pipe. It is mainly used for processing the plate edge. Through the high-speed rotation of the milling cutter disc, the weld groove is opened for the edge of the steel strip. It is for ensuring the weld quality of the welded pipe. Plays a very important role.

The production process of edge miller mainly includes raw material preparation, feeding, positioning and clamping, edge milling, edge quality inspection, blanking, cleaning and maintenance, etc. Through these steps, it can be ensured that the produced spiral welded pipe has high-quality edges, which lays a good foundation for the subsequent forming and welding process.

In the fast-paced market competition, time is productivity, and efficiency determines the future. Therefore, Huaye edge miller at the beginning of the design into the efficient, stable, easy to maintain the concept. This means that from the moment you place an order, we have started an efficient engine, and strive to deliver the high quality edge milling machine to your hands in a short time to easily cope with the order peak and realize worry-free delivery.

Choose Huaye, is to choose a trustworthy partner, if you have the need, welcome to contact us yang.wang@huaye.us!

Key words:

Pipe welding equipment

Related News

Working principle and application of spiral welded pipe machine

2024-09-09

Development direction of spiral welded pipe machine

2024-09-09

Matters needing attention when using spiral welded pipe machine

2024-09-09