Contact Us

Uzi Complete set of 1620mm rear swing bridge API Spiral Pipe Production Line

25 Sep,2024

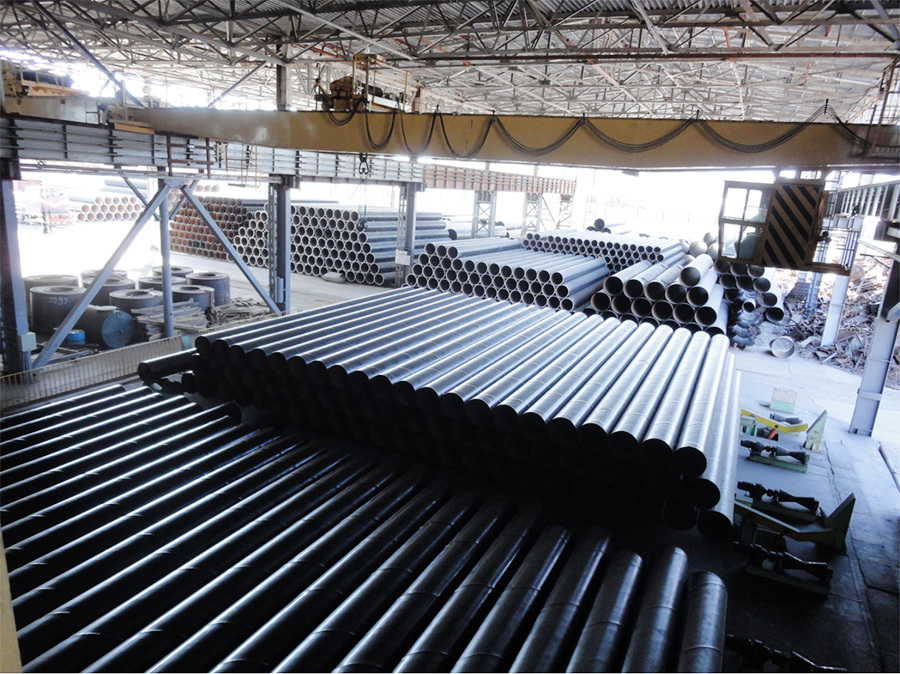

Uzbekistan 1620 pendulum screw welding API complete set of equipment

The Uzbekistan 1620 API spiral pipe plant project was completed by Huaye in 2009. The total investment in the project equipment exceeded 10 million US dollars. The full set of equipment for this project includes: spiral pipe mill section; end facing and beveling machine; hydrostatic tester; X-ray flaw detection equipment; pipe expander; other finishing area equipment (conveyor, pipe ejector, rack, slag removing machine, rotating roller, weighing equipment, etc.)

This set of equipment is the use of rear swing molding, uninterrupted continuity of production methods greatly improved production efficiency. The annual output can reach 160000 tons, and API X70 material can produce spiral steel pipes with a maximum diameter of 1620mm and a maximum thickness of 25.4mm.

The completion of the Uzbek 1620 pendulum screw welding API complete equipment project by Huaye is an important achievement. The successful completion of the project indicates that Huaye's technical strength and service level in the international market have been fully affirmed and recognized. This cooperation not only further strengthens the reputation of Huaye in the international engineering field, but also contributes to the development of Uzbekistan's energy industry. Huaye will continue to uphold the efficient and professional work attitude, provide more high-quality engineering solutions for international customers, and become a reliable partner.

Key words:

Pipe welding equipment

Related News

From Raw to Ready: How Pipe Prepping Machines Transform Your Workflow

2025-12-13

Essential Insights into Pipe Prepping Machines: A Comprehensive Guide

2025-12-08

How to Ensure Your Pipe Welding Equipment Meets Industry Standards

2025-12-03