Contact Us

Steel Pipe Convey System of Welded Pipe Production Line

Key words:

Product category:

Product Details

Steel Pipe Convey System of Welded Pipe Production Line

Product Introduction

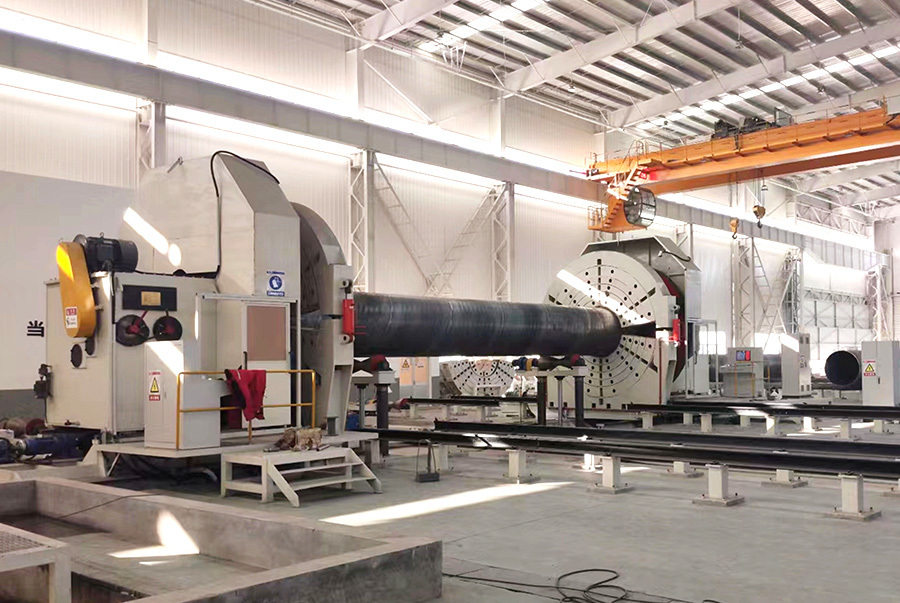

The finishing part of the steel pipe production line refers to a series of subsequent equipment after the steel pipe leaves the production equipment. In actual production, the finishing part is often referred to as the steel pipe transfer system. This part of the equipment includes roller table, bench, pipe dial, pipe dial, rotating idler, pipe transport trolley and some other simple steel pipe follow-up treatment equipment, such as welding slag dumping equipment, weld grinding equipment, etc.

Experienced engineers of Huaye provide scientific and reasonable workshop layout and steel pipe transportation solutions for customers according to the plant conditions provided by customers. According to the plan, Huaye can provide customers with a one-stop supply of steel pipe finishing equipment. To provide maximum support for the production of steel pipes for customers.

How to obtain the overall production process layout?

1. Determine the main equipment required by the factory

2. Determine factory size or site size

3. Provide or confirm workshop drawing

4. Huaye will design the workshop layout according to the required equipment and confirmed workshop drawings.

Finishing part of the main equipment

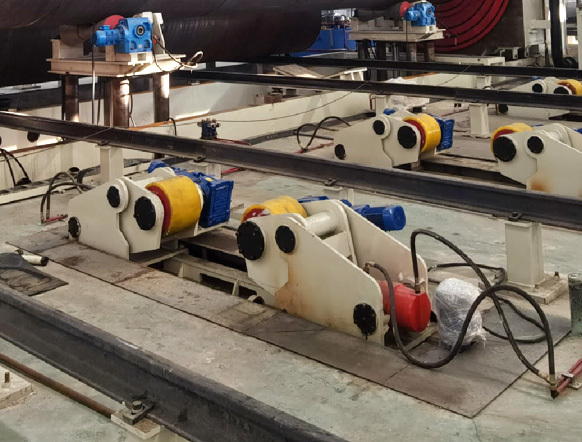

Swing rotating idler

Used to lift and rotate the steel pipe, generally used for welded pipe repair welding, manual inspection, etc. | Ducer

Used to move the steel pipe, often used to pull the steel pipe from the roller table or roller to the bench. |

Pipe trolley

For the horizontal transportation of steel pipes, it can replace the pipe dial to realize the transmission of steel pipes between the bench and the roller table. | Repair welding station

Used to repair the defective part of the steel pipe weld, including rotating roller, (or swing rotating roller), (welding arm), repair welding machine. |

Active roller table

| Passive roller table

|

| For longitudinal transportation of steel pipes | |

Rotating idler

Used to rotate the steel pipe, generally used for welded pipe repair welding, manual inspection, etc., often with the use of the tube | Rotating pipe carrying trolley

For 90 ° rotation in the transport direction of the steel pipe |

Welding slag dumping device

Used to dump the welding slag inside the steel pipe | Tube drop

Used to gently drop the steel pipe on the bench or the next production stage |

Huaye and Customers

Shipping

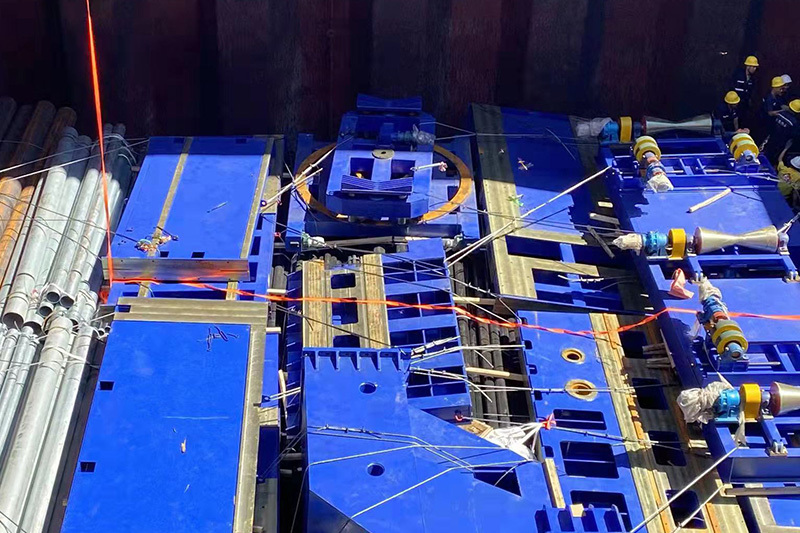

Although the welded pipe equipment itself has a large volume and weight, it is basically modular. We will try our best to design each module into a standard container.

But there are always some special parts, no matter how to change the design also exceed the volume size of the container. At this time we will use frame containers or open top containers.

If there are too many overweight or oversized parts, we will also choose bulk carriers for shipment.

Previous:

Next:

Product inquiry

* Please leave your contact information and we will contact you within 24 hours.