Contact Us

Spiral pipe Machine

Key words:

Pipe welding equipment

Product category:

Product Details

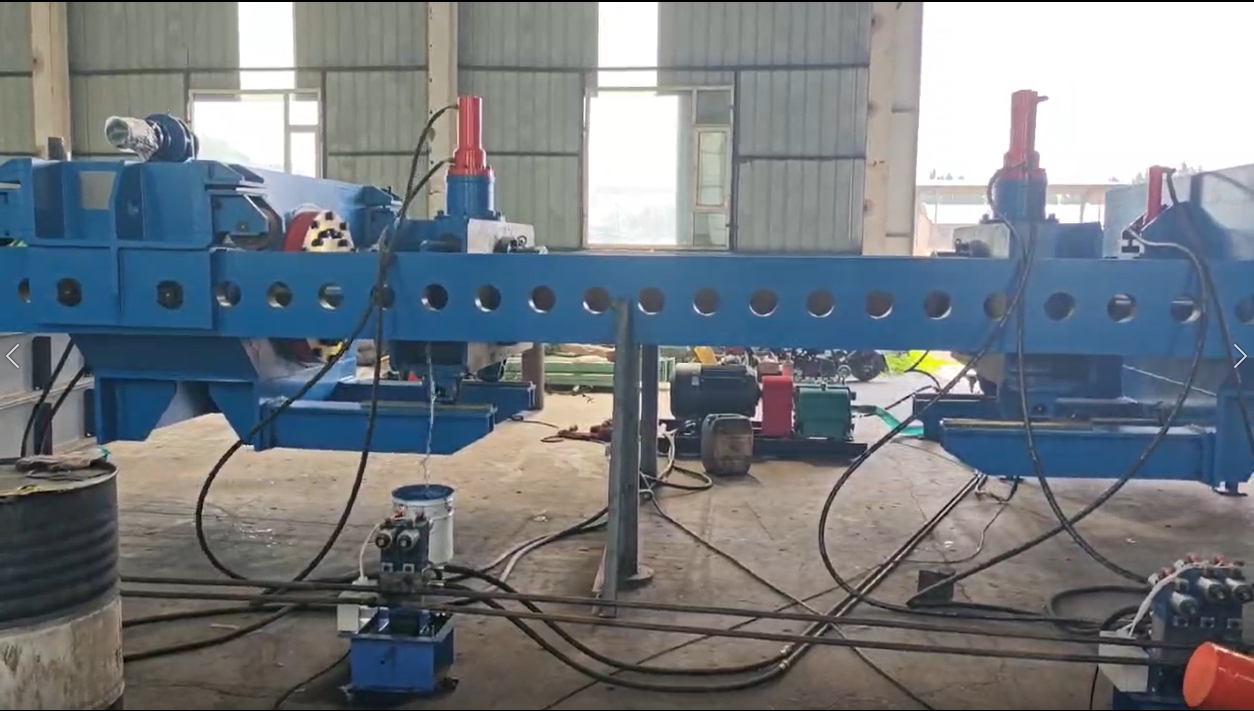

Spiral Pipe Machine

Product Introduction

Spiral pipe Machine is a steel pipe formed by rolling low-carbon carbon structural steel or low-alloy structural steel strip into a tube blank by a forming machine according to a certain forming angle, and then welding the spiral pipe seam with a submerged arc welding machine. The advantage is that a narrow strip can be used to produce large diameter steel pipe.

use of spiral welded pipe:

• For liquid transportation: water supply and drainage;

• For gas transmission: gas, steam, liquefied petroleum gas;

For structural use: pile driving pipe, bridge, wharf, road, building structure pipe, etc.

Process flow:

Roll-up → uncoiling → leveling → shearing butt welding → disc shearing → edge milling → delivery machine → pre-bending guide plate → forming → internal welding → external welding → cutting off → pulling out → flat head chamfering → hydraulic test → finished product collection

The spiral welded pipe production line is a mature mill with very competitive and technical characteristics in Huaye. The product specifications range from Φ25mm to 4000 Φmm, and are divided into general units and special customized units.

Many domestic firsts and domestic firsts fully demonstrate the strong technological advantages of Huaye and the research and development capabilities of many cutting-edge technologies.

The first set of domestic (the second set in the world) aluminum-magnesium alloy (small hole welding method) Φ200-914 spiral welded pipe mill.

• The smallest domestic spiral welded pipe unit Φ25-114 stainless steel spiral welded pipe production line.

China's first set of spiral welded pipe complete sets of unit export project Φ508-1800 mill (API standard)

• A domestic user mass production of 9 sets of spiral welded pipe unit (complete delivery within four months).

Specifications and models

| Model Series | Minimum pipe diameter | Maximum pipe diameter | Minimum wall thickness | Maximum wall thickness | Adapt to plate width | Maximum production capacity | Floor Area |

| mm | mm | mm | mm | mm | ton/year | m2 | |

| LH500 | 219-508 | 325-820 | 2-4 | 4-10 | 400-600 | 8000-12000 | 20X96 |

| LH750 | 219-508 | 406-1220 | 2-4 | 4-12 | 400-600 | 9000-17000 | 20X96 |

| LH1050 | 219-508 | 630-1620 | 2-4 | 4-14 | 450-1050 | 16000-23000 | 24X108 |

| LH1250 | 406-610 | 820-1620 | 3-6 | 8-18 | 500-1250 | 26000-35000 | 24X108 |

| LH1550 | 406-610 | 1420-4800 | 3-6 | 12-30 | 500-1550 | 36000-76000 | 26X125 |

| LH2000 | 406-610 | 2020-4800 | 4-6 | 20-30 | 1000-2000 | 77000-93000 | 30X180 |

The above models are for reference only and can be customized according to customer needs

Special customized production line

Huaye and Customers

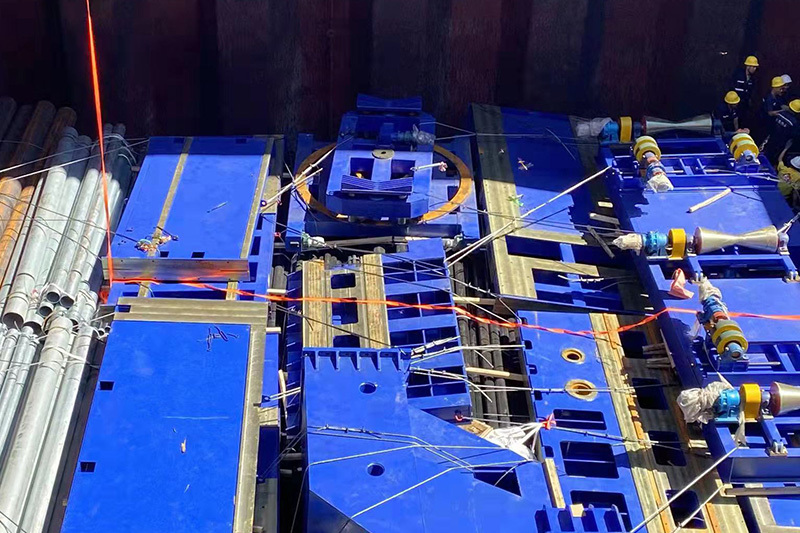

Shipping

Although the welded pipe equipment itself has a large volume and weight, it is basically modular. We will try our best to design each module into a standard container.

But there are always some special parts, no matter how to change the design also exceed the volume size of the container. At this time we will use frame containers or open top containers.

If there are too many overweight or oversized parts, we will also choose bulk carriers for shipment.

Previous:

Product inquiry

* Please leave your contact information and we will contact you within 24 hours.